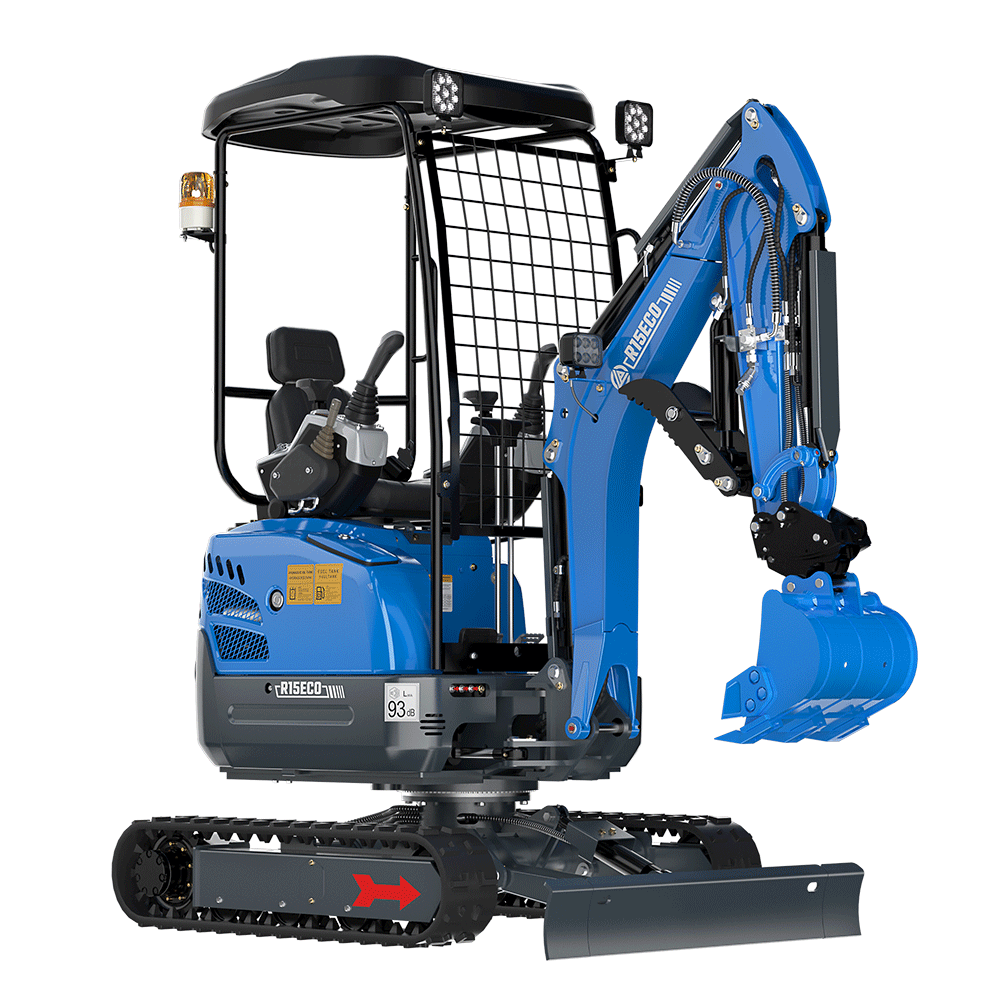

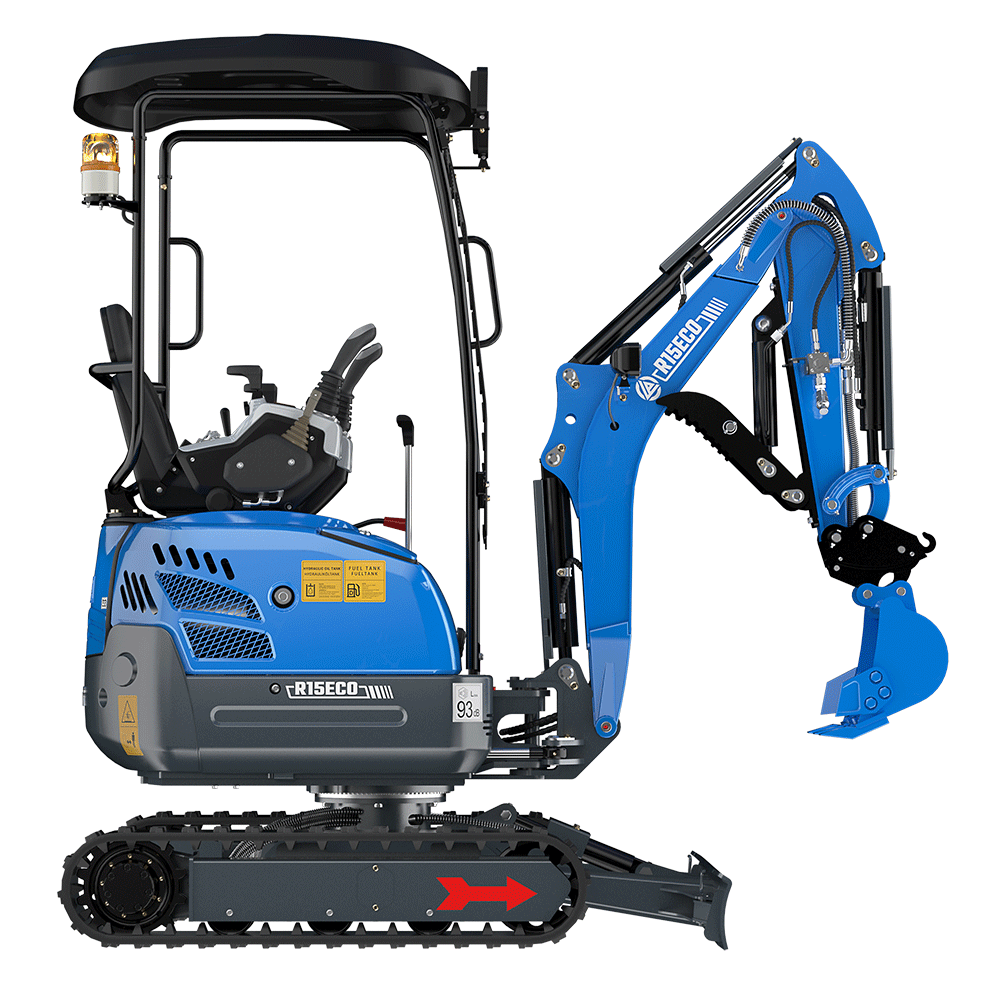

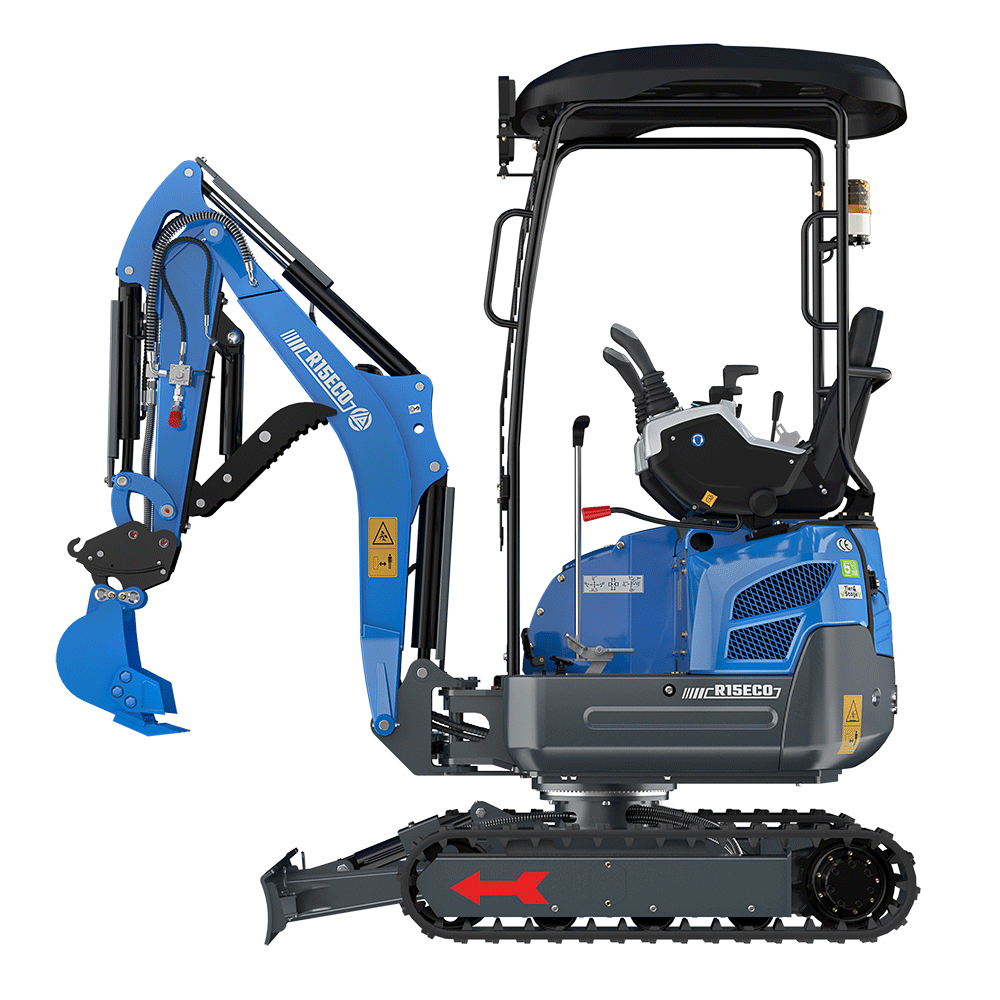

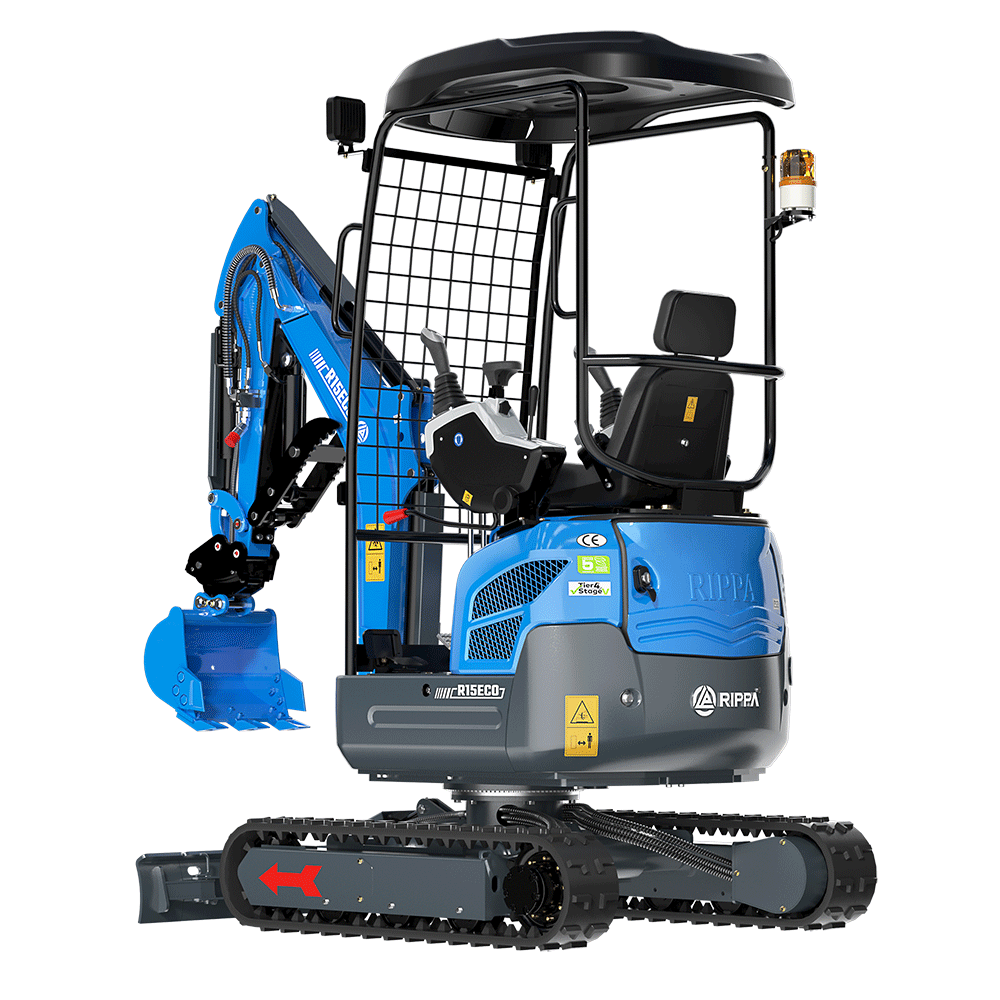

micro mini excavator

Global Agent Recruitment

We are now recruiting agents worldwide!

Ideal for businesses and dealers – Start with just one unit for your overseas warehouse.

Tailored for construction projects – Wholesale only, not for retail.

Local inventory advantage – Warehouses near you ensure fast delivery and a full range of accessories.

24/7 customer support – Always here to assist you.

👉 Fill in your details, get a quick quote, and join us as our valued agent today!

Advanced Control System for Smooth Operation

The excavator is equipped with a full pilot control system, featuring a dual pilot foot valve and two single pilot foot valves. This setup significantly improves the overall configuration of the machine, allowing operators to enjoy smoother and more stable control. By adopting this advanced design, the operator’s driving experience becomes more intuitive and efficient, ensuring precision during complex excavation tasks.

In addition, the hydraulic hose layout has been carefully optimized. With a more structured pipeline arrangement, friction and wear between hoses are minimized, reducing maintenance costs and extending the service life of the hydraulic system. This smart engineering upgrade provides not only reliability but also long-term durability, which is crucial in high-intensity excavation projects.

Enhanced Lighting and Safety Features

For nighttime operations, the excavator is designed with an upgraded lighting system. A set of nine high-beam roof-mounted lamps has been added to maximize visibility in low-light conditions. The original rocker switch has been replaced with a two-stage switch: the first stage activates the working lamp, while the second stage powers both the working lamp and the high beams. This system ensures operators can adjust lighting flexibly based on their environment, greatly improving safety during late-night or poorly lit construction work.

The improved visibility not only prevents accidents caused by poor lighting but also enhances the operator’s field of vision during operation. By integrating this advanced illumination design, the machine ensures that both safety and efficiency are maintained regardless of the time of day.

Improved Handling in Complex Terrains

The excavator’s discharge motor base now includes a lifting port, which significantly improves the machine’s loading and unloading capabilities in challenging terrains. This feature allows for complete lifting and handling flexibility, enabling the excavator to adapt to demanding environments where maneuverability and stability are essential.

With this enhancement, the excavator is better equipped to handle unexpected situations, such as recovery from difficult ground conditions or performing precise lifting tasks in restricted spaces. This makes it a reliable choice for operators who frequently work in rugged construction or mining areas.

Durable Grease Nipples for Long-Term Maintenance

To further extend durability, the excavator integrates nickel-plated grease nipples. This coating effectively prevents corrosion caused by water, mud, and acidic or alkaline substances. By enhancing surface hardness, the design also reduces deformation under high-pressure lubrication, ensuring that the lubrication system remains intact and functional over long-term use.

The excavator is also equipped with pointed grease nipples for more precise alignment with grease guns. This prevents slippage or leakage during the lubrication process, making maintenance easier and more reliable. To protect the grease fittings from operational damage, a welded stopper is added, which shields the components during heavy-duty work.

Operators are advised to follow proper lubrication guidelines for optimal performance. Each grease nipple should be inspected every 50 to 100 working hours to ensure it is not blocked or damaged. Before lubrication, the surface should always be cleaned to prevent impurities from entering the system. Using a high-pressure grease gun (≥3000 psi) is recommended to ensure the grease fully penetrates into the pins, enhancing long-term reliability of the excavator.

Related News

Submitted successfully

We will contact you as soon as possible