china made hydraulic excavator

Global Agent Recruitment

We are now recruiting agents worldwide!

Ideal for businesses and dealers – Start with just one unit for your overseas warehouse.

Tailored for construction projects – Wholesale only, not for retail.

Local inventory advantage – Warehouses near you ensure fast delivery and a full range of accessories.

24/7 customer support – Always here to assist you.

👉 Fill in your details, get a quick quote, and join us as our valued agent today!

Key Features of Excavators Made in China

The China excavator market has gained global recognition due to its continuous improvements in design, technology, and performance. Many excavators made in China are now equipped with advanced safety systems, ensuring reliable operation in tough working conditions. For instance, the hydraulic quick-change control rocker switch is enhanced with dual mechanical insurance, providing extra protection and minimizing operational risks.

Another major improvement lies in the optimization of hydraulic quick-change pipelines. By adjusting the layout, these machines reduce resistance, improve oil flow efficiency, and extend the service life of hydraulic components. The addition of four-way high-pressure breaker pipelines allows operators to handle multiple attachments, enhancing versatility for construction, demolition, and agricultural projects.

Ergonomic and Safety Enhancements in Manufacturing Mini Excavator

Manufacturers have prioritized operator comfort while manufacturing mini excavator models. The joystick system has been upgraded to dual-button handles, enabling easier control. Operators can switch between swing and deflection directly through the left-hand button, simplifying complex movements. A newly added forward and reverse hand-switching device ensures smoother control, which is particularly useful in confined spaces.

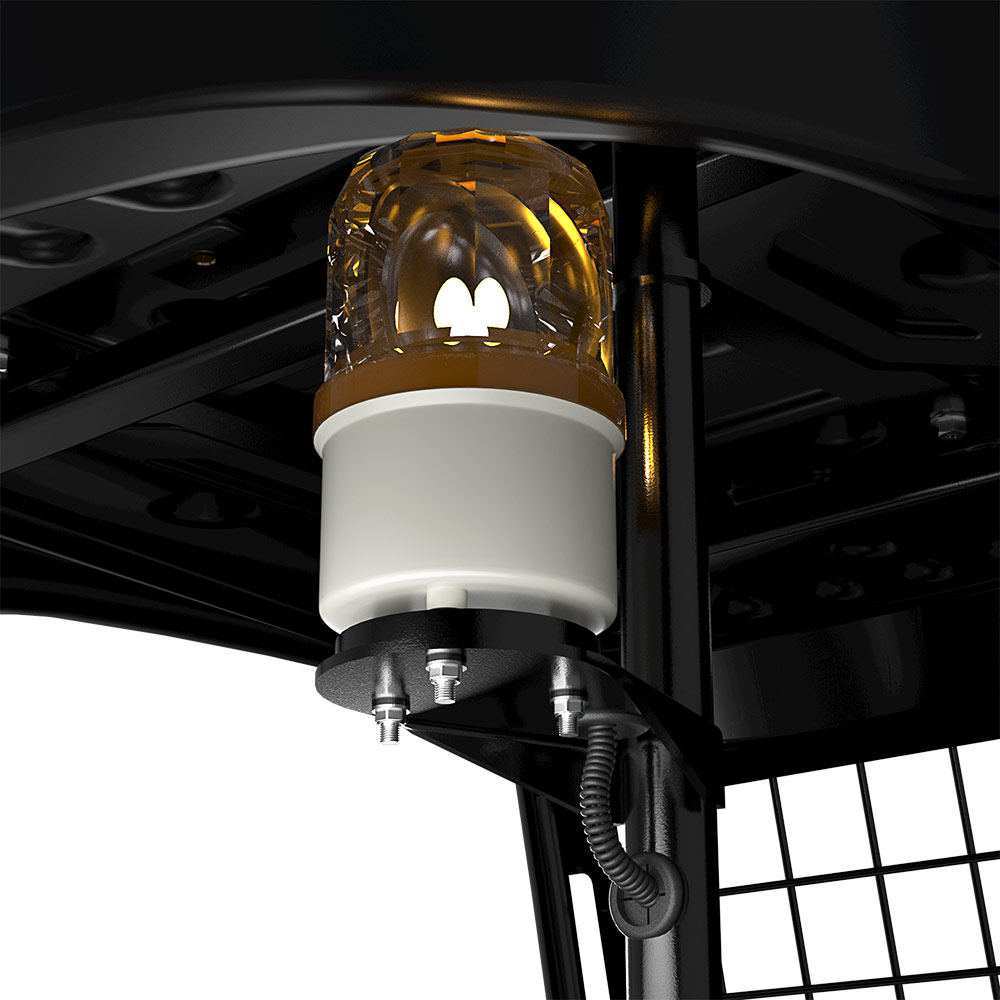

For safety upgrades, the warning lights that once relied on magnetic bases have been replaced with a bolt-mounted installation. This ensures greater stability during long operations and reduces the risk of disconnection in rough terrains. At the same time, the machines have shifted entirely to a full pilot control system, removing the traditional mechanical control form. This change improves overall handling smoothness, reduces fatigue, and elevates the overall performance of excavators made in China.

Structural and Durability Upgrades in the China Excavator Market

Durability and stability are crucial in the China excavator market, especially for projects requiring long operating hours. The pipeline arrangement has undergone further optimization to minimize wear and improve oil circulation efficiency. To enhance working conditions during low-light hours, a front roof lamp has been added, giving operators a clearer field of view.

Thermal management has also been upgraded with the installation of engine compartment insulation cotton, preventing overheating and extending engine life. The lower chassis motor now features an additional lifting port, simplifying transportation and maintenance tasks. Moreover, all pipelines are fitted with grease nipple protectors, using pointed grease nipples to reduce contamination risks and ensure reliable lubrication.

Additional structural upgrades include a protective cover for the ignition switch, which prevents dust, water, and accidental damage. To ensure operator stability, anti-slip rubber mats have been installed in the cabin, reducing the chance of slips and increasing comfort during extended operations. These thoughtful enhancements further establish excavators made in China as globally competitive machinery.

Related News

Submitted successfully

We will contact you as soon as possible