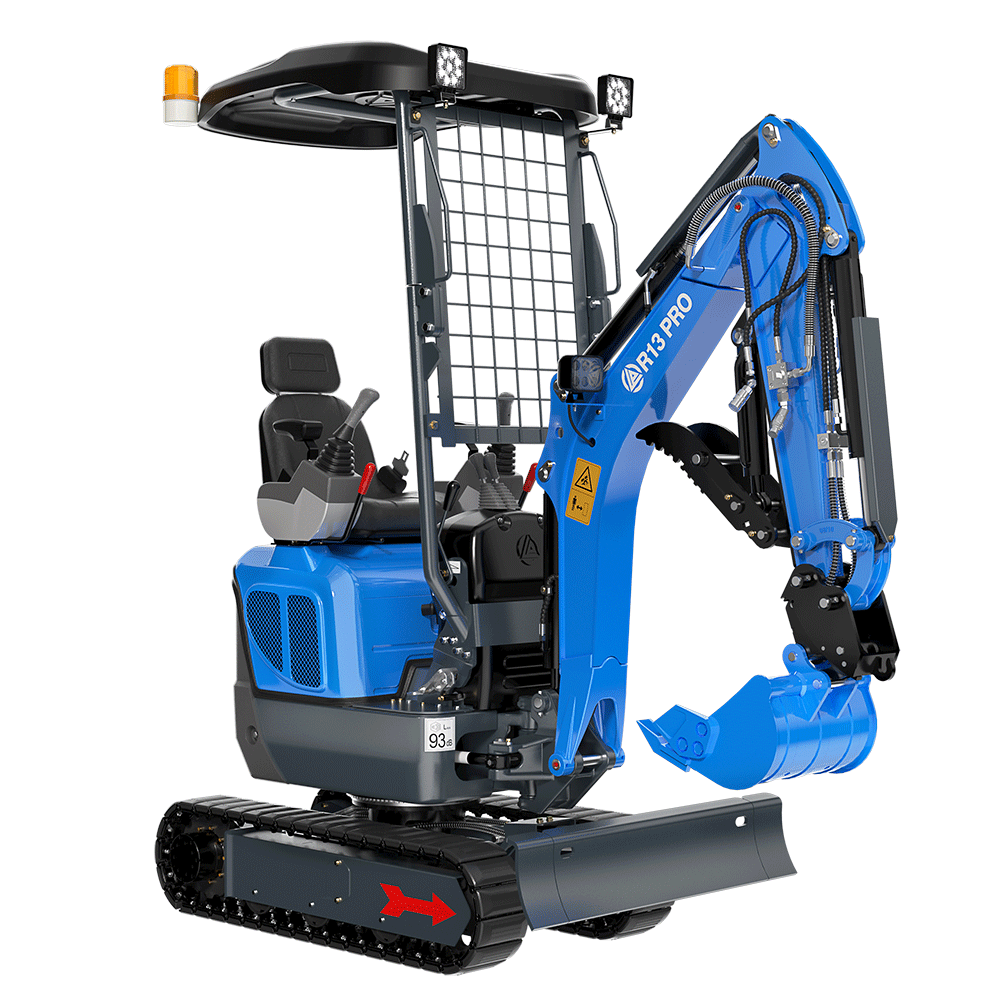

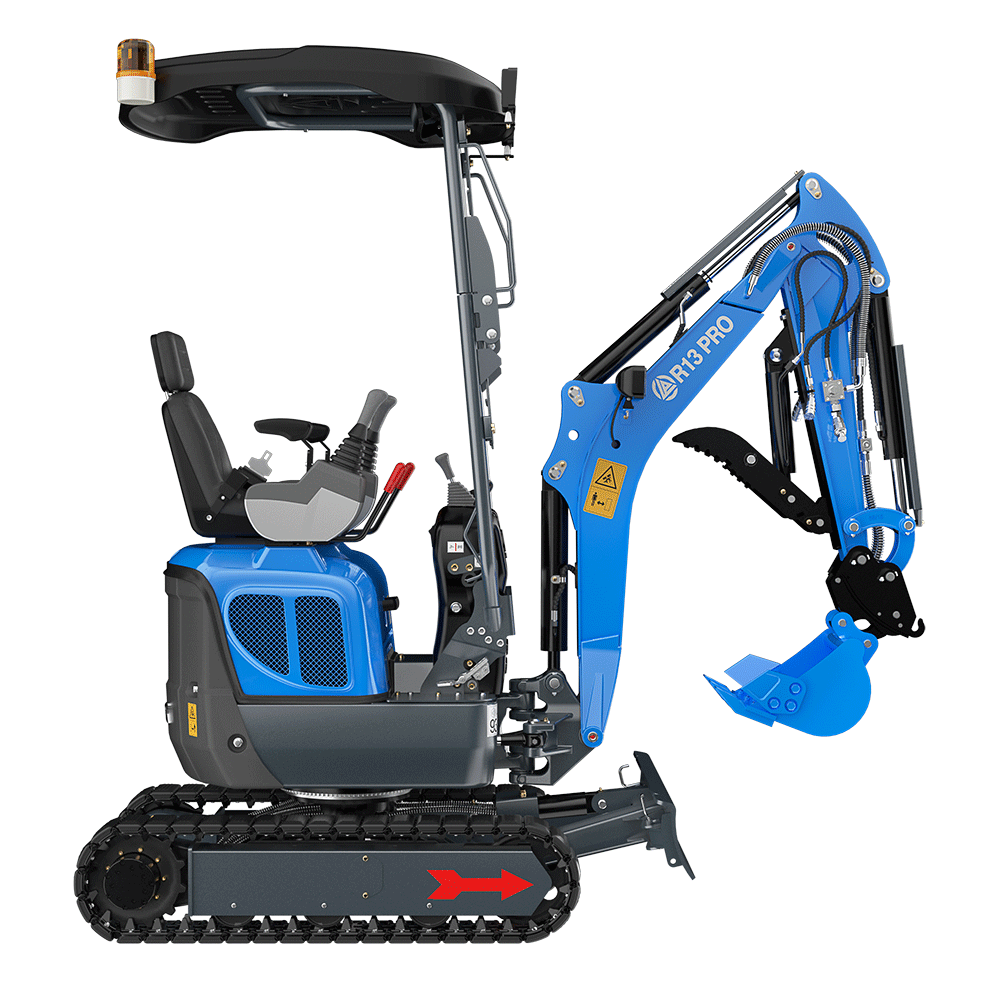

mini backhoe for sale

Global Agent Recruitment

We are now recruiting agents worldwide!

Ideal for businesses and dealers – Start with just one unit for your overseas warehouse.

Tailored for construction projects – Wholesale only, not for retail.

Local inventory advantage – Warehouses near you ensure fast delivery and a full range of accessories.

24/7 customer support – Always here to assist you.

👉 Fill in your details, get a quick quote, and join us as our valued agent today!

Advanced Features of Skid Steer Equipment

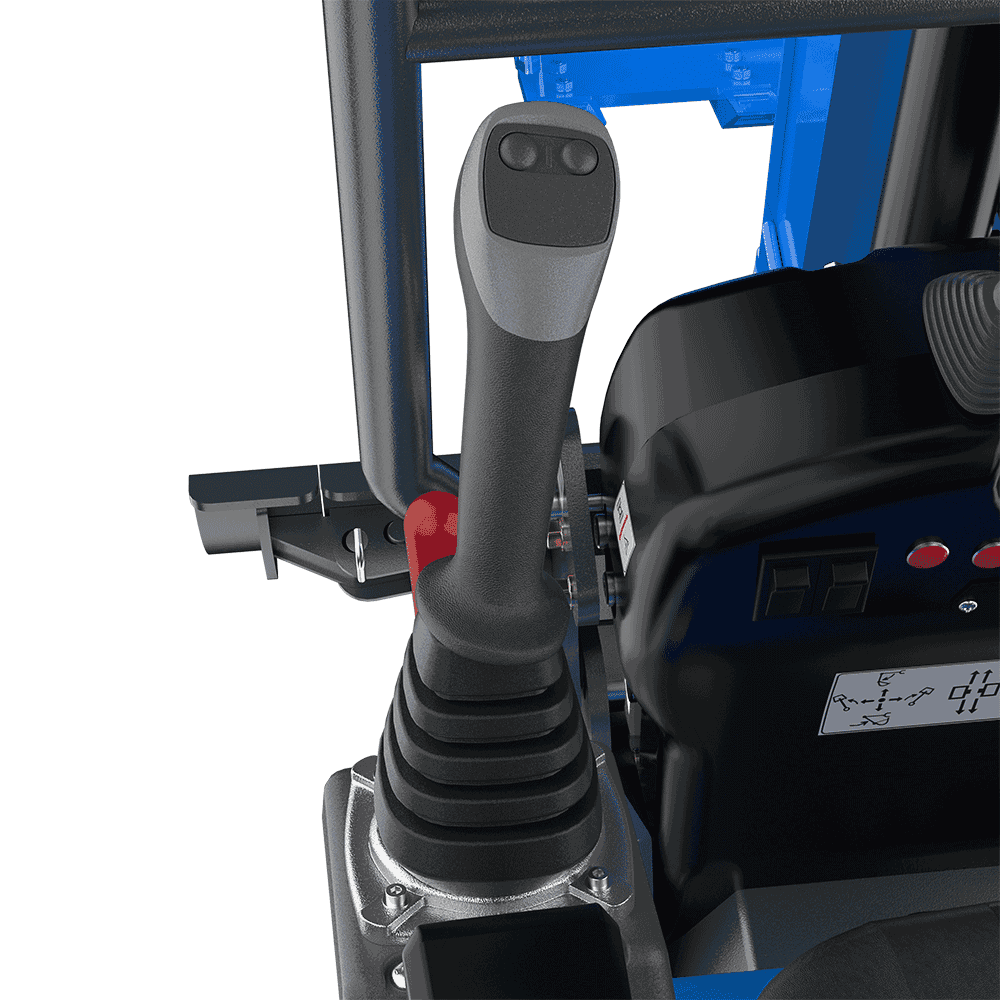

Convenient Handle Controls

Modern skid steer equipment is designed with dual guide button handles on both sides of the operator’s seat. Each handle is equipped with two buttons that allow control of the machine’s functions, including attachments and movement. The buttons are positioned directly above the handles, making them small, accessible, and convenient to use.

This design reduces operator fatigue, even during long working hours. By minimizing hand movement and keeping controls within easy reach, skid steer loaders ensure smoother operation and higher productivity across different job sites.

Durable Rear Arm Cylinder for Heavy-Duty Tasks

One of the most important structural features of advanced skid steer loaders is the placement of the rear arm cylinder. This design allows the bucket to pick up large rocks, concrete blocks, or other heavy materials without risking damage to the cylinder. Operators can also load materials directly into dump trucks or use on-board breakers for crushing tasks with confidence in the machine’s durability.

By protecting the arm cylinder from impact stress, the skid steer equipment maintains long-term performance and reduces the likelihood of costly repairs. This feature ensures reliability in demanding construction and mining applications where heavy loads are handled daily.

Safety and Comfort Enhancements

Safety is a top priority in modern skid steer equipment. The machine includes an operation lock lever that integrates a neutral start function. The engine cannot start unless the lock lever is raised, providing an extra layer of security to prevent unintended movements during startup.

For comfort, the skid steer loader features a sliding seat with four adjustable positions. Operators can modify the seat according to their body type, ensuring a more ergonomic and comfortable posture throughout long shifts. Additionally, an extendable safety belt is provided to keep the operator secure.

When using the ROPS (Roll Over Protective Structure) system, it is essential that operators fasten their seat belts. This combination of adjustable seating, safety belt integration, and protective systems ensures that the skid steer equipment delivers not only efficiency but also a safe working environment.

Submitted successfully

We will contact you as soon as possible