mini excavator pricing

Global Agent Recruitment

We are now recruiting agents worldwide!

Ideal for businesses and dealers – Start with just one unit for your overseas warehouse.

Tailored for construction projects – Wholesale only, not for retail.

Local inventory advantage – Warehouses near you ensure fast delivery and a full range of accessories.

24/7 customer support – Always here to assist you.

👉 Fill in your details, get a quick quote, and join us as our valued agent today!

Advanced Operator Comfort and Cabin Design

Modern excavators prioritize operator comfort, recognizing its direct impact on productivity and precision. The integration of a cabin fresh air system ensures a continuous supply of filtered air, creating a healthier and more pleasant working environment, especially in dusty conditions. This is complemented by readily available glass water for clear visibility and shock-absorbing blocks at the four corners of the cab, which significantly reduce vibrations and noise transmitted from the machine's main frame.

A key development in operator ergonomics is the application of large-model shock-absorbing seats. These seats are designed to dampen the jarring impacts and constant vibrations encountered during operation, drastically reducing operator fatigue over long working hours. This focus on comfort allows the operator to maintain higher levels of concentration and control, leading to more efficient and accurate work.

The functionality of the excavator cab is further enhanced by its thoughtful design, which includes the application of heat insulation mats. These mats are strategically placed to block radiant heat from the engine and hydraulic system, maintaining a cooler cabin temperature. This attention to detail provides a better overall operational experience, allowing the operator to work comfortably even in high ambient temperatures.

Robust Engineering for Durability and Maintenance

Durability and ease of maintenance are critical in heavy machinery. A significant feature is the standardization on unified, nationally standardized M10*1 nickel-plated pointed grease fittings. This uniformity simplifies the maintenance process, allowing service technicians to use a single tool for all lubrication points, reducing downtime and the potential for error. Furthermore, critical components are protected by welded blocking pieces that shield them from direct impact and debris during operation.

The excavator's hydraulic robustness is evident in its arm cylinder design, which incorporates a built-in cushioning mechanism. This feature controls the speed of the cylinder at the end of its stroke, preventing harsh metal-to-metal contact and reducing stress on the entire hydraulic system. This directly contributes to the long-term structural integrity of the boom and arm, minimizing wear and tear.

The excavator's hydraulic robustness is evident in its arm cylinder design, which incorporates a built-in cushioning mechanism. This feature controls the speed of the cylinder at the end of its stroke, preventing harsh metal-to-metal contact and reducing stress on the entire hydraulic system. This directly contributes to the long-term structural integrity of the boom and arm, minimizing wear and tear.

Enhancing versatility, the machine is equipped with dedicated connections for various attachments. A specific return line connection for a brush cutter is pre-installed, and the hydraulic system includes a three-way ball valve. This valve allows for easy switching of hydraulic flow, enabling one circuit to be dedicated to a powerful tool like a hydraulic breaker or crusher, while maintaining other auxiliary functions.

Superior Control and Critical Safety Systems

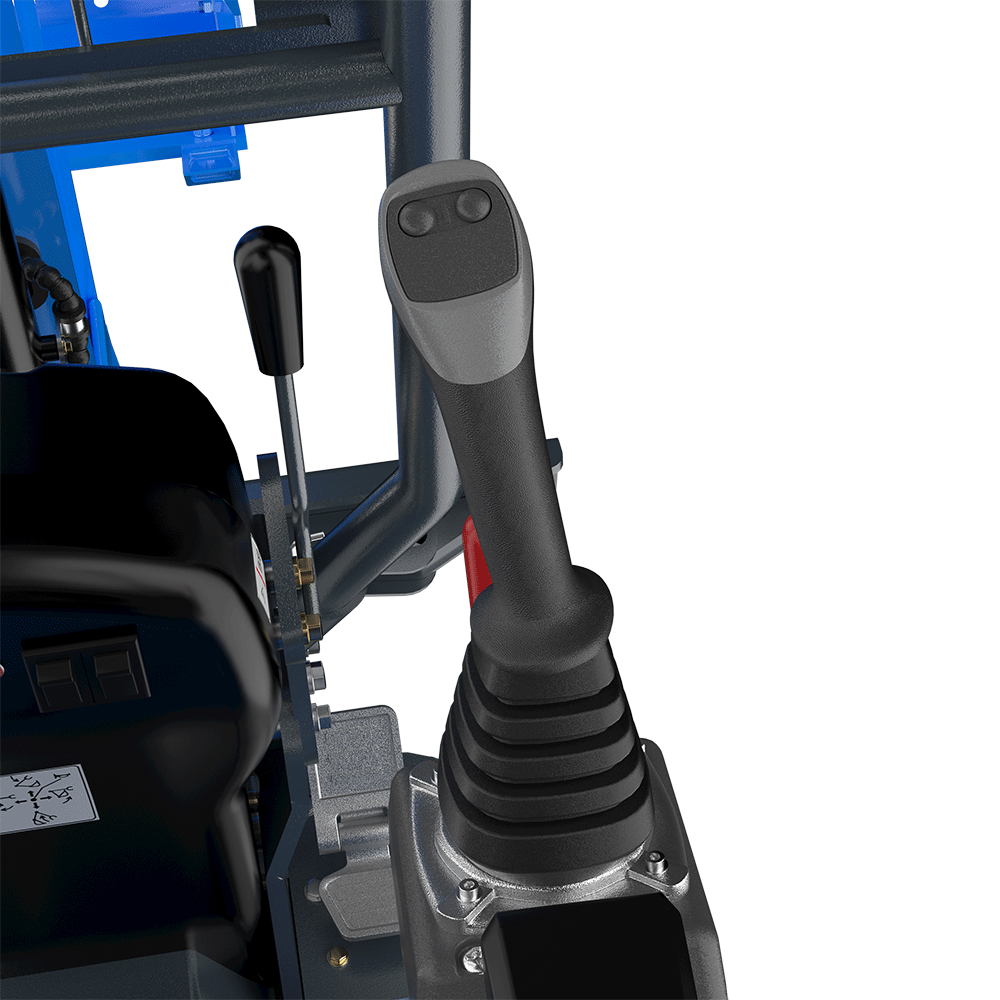

Precise control is achieved through the use of brand-model dual-button pilot control handles. These ergonomic handles provide smooth and responsive command over the excavator's movements. A dedicated function on the handle allows for effortless control of the upper structure's offset, providing greater flexibility in positioning the attachment without needing to reposition the entire undercarriage.

Safety is paramount, and this is addressed with several integrated systems. The boom cylinder is equipped with an anti-rupture valve, a critical safety device. In the event of a sudden hydraulic hose failure or rupture, this valve instantly locks the hydraulic oil within the cylinder, preventing the arm from dropping uncontrollably. This effectively safeguards both the operator and the worksite from potential accidents caused by a sudden loss of hydraulic pressure.

The machine's versatility is powered by a high-pressure, 4-circuit auxiliary hydraulic pipeline system. This robust system can deliver the necessary flow and pressure to operate a wide range of sophisticated attachments, from grapples and augers to compactors and multi-processors. The high-pressure rating ensures that each attachment performs at its peak capability, expanding the machine's functionality beyond basic digging and lifting tasks.

Related News

Submitted successfully

We will contact you as soon as possible