used mini skid steer loader

Global Agent Recruitment

We are now recruiting agents worldwide!

Ideal for businesses and dealers – Start with just one unit for your overseas warehouse.

Tailored for construction projects – Wholesale only, not for retail.

Local inventory advantage – Warehouses near you ensure fast delivery and a full range of accessories.

24/7 customer support – Always here to assist you.

👉 Fill in your details, get a quick quote, and join us as our valued agent today!

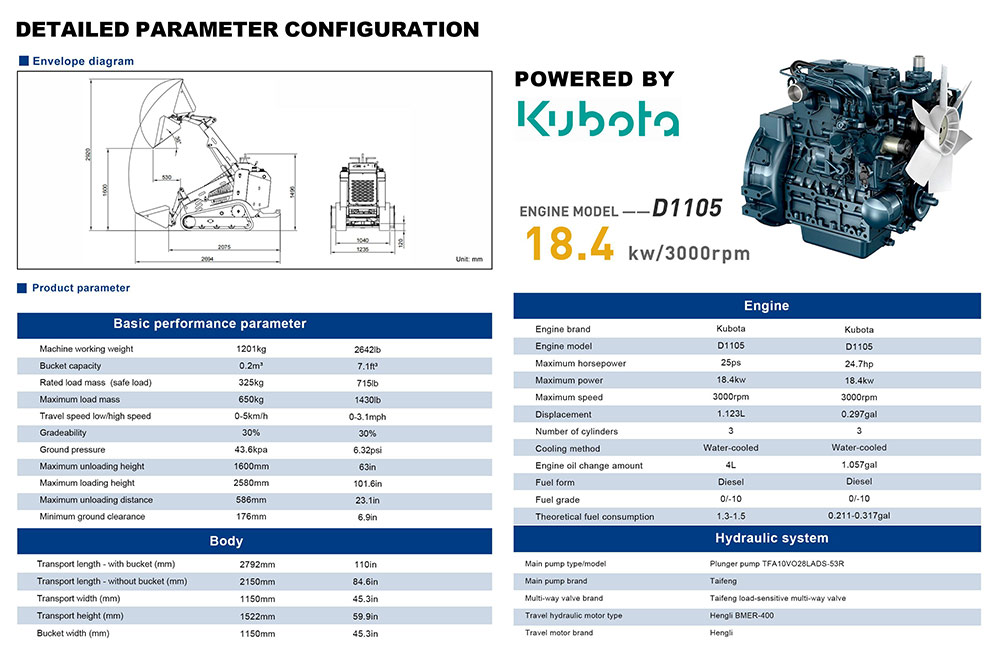

Superior Powerplant: The Kubota D1105-E4B-CWL-1 Engine

This skid steer loader is powered by the advanced Kubota D1105-E4B-CWL-1 engine, a benchmark for performance and compliance in compact machinery. Delivering a robust 18.2 KW (24.8 horsepower), this engine provides ample power for demanding tasks such as loading, digging, and lifting heavy materials. The high torque output ensures responsive performance even under full load, making it highly efficient for a variety of job site applications. This reliable power source is designed for longevity and consistent operation in challenging environments.

A standout feature of the D1105 engine is its adherence to the world's most stringent emission regulations. It holds both EPA Tier 4 Final and European Stage V certifications, demonstrating its clean-operating credentials. This dual certification means the engine significantly reduces harmful particulate matter and nitrogen oxide emissions without sacrificing the powerful performance operators expect from Kubota. This compliance makes the machine suitable for use in environmentally sensitive areas and strict regulatory zones, future-proofing your investment.

Ergonomic Design for Enhanced Operator Comfort and Serviceability

Operator comfort is paramount, and this model features a meticulously designed open-mold lumbar support cushion. This ergonomic seat provides critical lower back support, significantly reducing operator fatigue during long shifts. The enhanced comfort leads to greater concentration and productivity, as the operator can focus on precision tasks without discomfort. The interior cabin is laid out with intuitive controls, further contributing to a superior and less taxing operational experience.

Routine maintenance and quick inspections are simplified through an innovative increased service access point. The design incorporates an upward-flipping panel or compartment, allowing technicians to reach key components like the engine oil filter, fuel filter, and coolant reservoir with ease. This quick access drastically reduces downtime for daily checks and minor servicing, ensuring the machine spends more time working and less time in the workshop. This thoughtful engineering underscores a commitment to operational efficiency and total cost of ownership.

Advanced Stability and Versatility for Demanding Tasks

Stability is critical for safety and performance, especially during heavy lifting operations. This skid steer loader incorporates additional counterweights at the rear of the machine. This strategic placement effectively balances the heavy loads carried in the front attachment, preventing "tail lift" or tipping. The enhanced stability instills confidence in the operator when handling maximum capacity loads and improves the machine's overall heavy-duty作业 capability on uneven terrain.

Versatility is greatly expanded with the addition of front and rear tow hooks. These forged hooks are not just for towing trailers; they enable a wide range of functions including assisted lifting with slings, recovery operations for stuck vehicles, and even self-recovery. This multifunctional design increases the machine's practicality on any job site, from construction and landscaping to agricultural and industrial settings. The hooks provide robust anchor points for securing loads and performing light crane-like tasks, adding significant value.

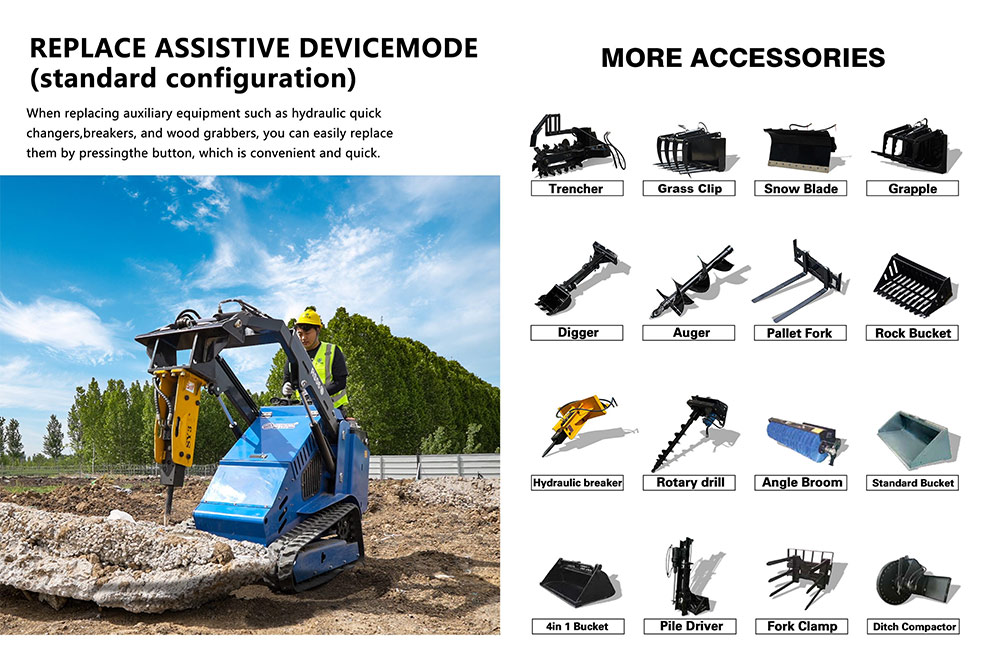

Precision Hydraulic System for Superior Attachment Control

The heart of the machine's capability lies in its high-flow hydraulic system, delivering 56 liters per minute to attachments. This substantial flow rate ensures that high-demand hydraulic tools like brush cutters, cold planers, and hydraulic hammers operate at their peak efficiency. The powerful hydraulic performance translates directly into faster cycle times and more effective material processing, boosting productivity on every project.

Control is managed by a dual-pilot control handle system. This intuitive setup allows for single-handed operation of both driving and attachment functions, leaving the operator's other hand free for steering or managing other controls. The pilot-operated valves provide smooth, proportional control, enabling delicate maneuvers with heavy attachments. Furthermore, the inclusion of a self-leveling valve is a significant productivity feature; it automatically maintains the bucket or fork angle during the lift arm's ascent, ensuring a level load without constant manual adjustment from the operator, which enhances safety and material retention.

The hydraulic system's architecture is designed for cleanliness and reliability. It features dual attachment circuits with neatly routed hydraulic lines. This organized routing not only gives the machine a professional, high-quality appearance but also protects the hoses from potential snags and damage, their service life. The linkage system utilizes a rocker arm and short connecting rod mechanism to achieve a true vertical lift path for the arms. This vertical lift capability allows the machine to reach greater dump heights and maintain consistent load positioning close to the machine, which is essential for loading over high walls or into deep containers.

Related News

Submitted successfully

We will contact you as soon as possible