The Ultimate Buyer's Guide to Mini Skid Steer Loaders (2025)

Finding the Right Compact and High-Performance Equipment

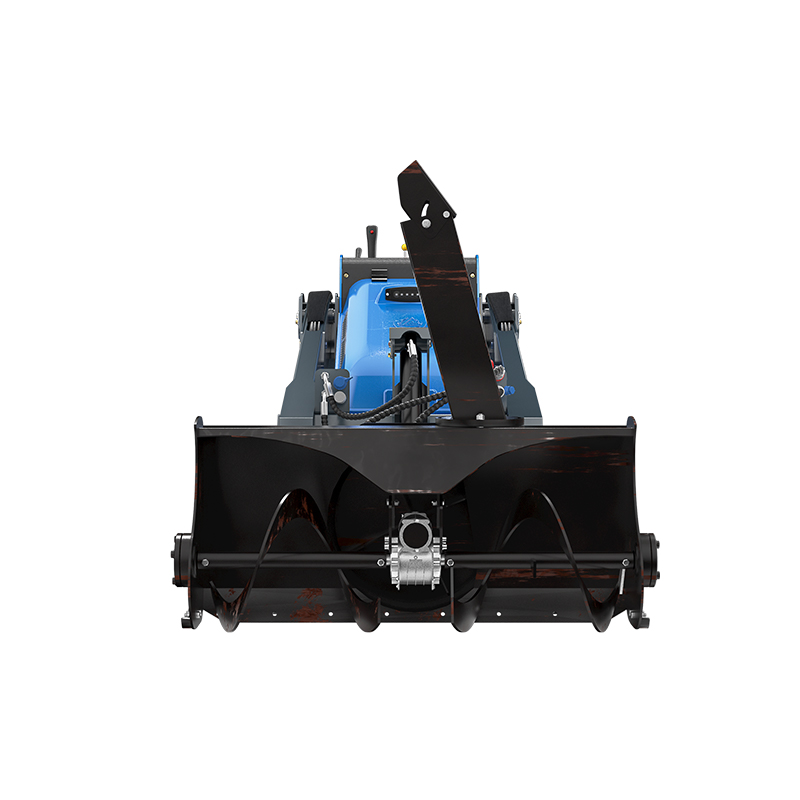

Modern job sites demand machines that combine power, precision, and compact design. The challenge lies in finding equipment that meets professional needs without being as bulky or costly as large machinery. The RIPPA R06 Mini Excavator perfectly meets this demand — it is a small, highly capable machine engineered for maximum efficiency in tight spaces.

This compact excavator offers a versatile and powerful solution for landscaping, construction, and property management. Despite its small body, the R06 delivers big performance, allowing operators to complete challenging jobs that once required larger and less efficient equipment.

Designed with global job demands in mind, the R06 Mini Excavator integrates advanced hydraulics, precise control systems, and a durable chassis. Whether you’re handling trenching, grading, or material loading, this machine adapts seamlessly to diverse work environments, making it an indispensable partner for professionals worldwide.

We’ve crafted this guide to help you fully understand what makes the RIPPA R06 Mini Excavator an exceptional choice. From exploring key features to understanding how attachments enhance versatility, this overview provides clear, reliable insights for choosing the right compact machine for your business.

What Is a Mini Skid Steer and Why It Matters

A mini skid steer or compact excavator like the R06 is far more than a downsized version of larger machines — it’s purpose-built for efficiency in restricted environments. Engineers designed it to deliver hydraulic power and lifting performance where traditional heavy equipment cannot reach.

Think of the R06 as a compact tracked power unit capable of performing tasks that would otherwise require multiple workers and hours of manual labor. It handles everything from digging and grading to carrying heavy materials and clearing tight worksites.

With its compact footprint, the R06 can navigate narrow alleys, urban job sites, and indoor spaces, all while maintaining impressive stability and digging strength. Its design combines a robust steel frame with a fuel-efficient engine, allowing professionals to reduce operational costs while achieving consistent performance.

The smart control system integrated into the R06 ensures smooth operation and precise maneuvering. Operators can work comfortably thanks to the ergonomic layout, intuitive levers, and responsive hydraulics that make even complex tasks manageable.

Common Questions About the RIPPA R06 Mini Excavator

1. What Regular Maintenance Is Required?

Routine maintenance is key to ensuring long-term reliability. Daily checks should include inspecting hydraulic levels, track tension, and engine oil. Regular replacement of filters and lubrication of pivot points will keep the R06 performing at its best. RIPPA’s thoughtful design includes easily accessible maintenance points, reducing downtime and improving overall productivity.

2. Can It Use Attachments from Other Brands?

Yes. The R06 Mini Excavator supports universal quick-attach couplers, allowing compatibility with various attachments from different manufacturers. However, always ensure that the attachment’s hydraulic flow and pressure requirements match the machine’s specifications for optimal safety and performance.

3. How Does It Compare to Small Tractors?

While small tractors excel in fieldwork and towing applications, mini excavators like the R06 are designed for precision operations in confined spaces. The zero turning radius and superior lifting capability give the R06 an advantage in tight construction zones, where agility and speed are crucial.

4. How Steep a Slope Can It Handle?

Tracked machines like the R06 offer exceptional stability on slopes compared to wheeled models. Generally, it can safely operate on gradients between 20 to 25 degrees, depending on surface conditions. Always follow RIPPA’s operational guidelines to ensure maximum safety and control.

5. What Are the Benefits of the Standing Design?

For operators using stand-on variants or similar configurations, there are three key advantages: improved all-around visibility, faster on-and-off access for clearing debris or adjustments, and a smaller overall footprint. These benefits make the R06 ideal for tasks requiring frequent repositioning in compact environments.