backhoe loader china

🌍 Global Distributor Recruitment

RIPPA Machinery Group is now expanding worldwide and looking for reliable distributors to join our global network!

Our machines are fully certified with CE, EPA, Euro 5, and TUV, delivering the quality and performance trusted by customers around the world.

Why Partner With RIPPA?

🚚 Local Stock Advantage – Nearby warehouses for fast delivery and complete spare parts support.

🧰 Global After-Sales Service – Multiple international service centers offering professional technical support.

💪 Wide Product Range – Excavators, loaders, skid steers, forklifts, and more.

👉 Join Us Today!

Submit your details to receive a quick quote and become an official RIPPA distributor!

Power and Precision: A Deep Dive into the Rippa Mini Skid Steer

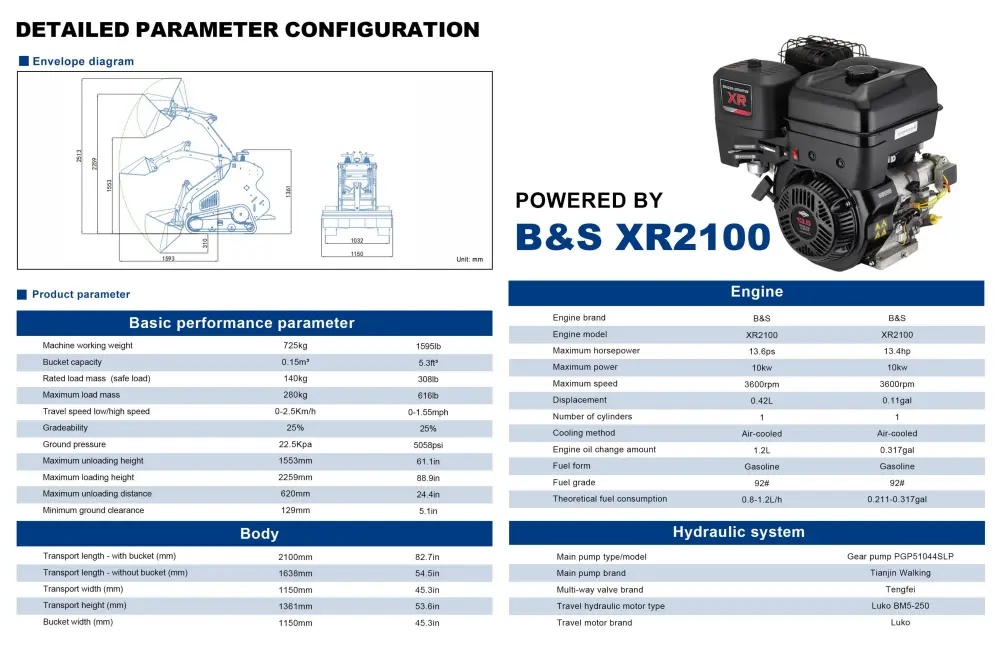

The Rippa mini skid steer is engineered to deliver exceptional performance in a compact, agile package. Its design prioritizes both power and operator comfort, making it a versatile and efficient choice for demanding job sites. A key feature of this machine is the inclusion of speed mode adjustment as standard equipment. This innovative system allows the operator to simply push a lever, which then automatically adjusts the engine RPM and selects the appropriate gear based on the selected work mode. This intelligent automation makes operation more intuitive and the entire workflow significantly more efficient.

Driving this performance is the reliable B&S XR2100 engine. This powerplant is renowned for its low fuel consumption, minimal vibration, and quiet operation, contributing to lower operating costs and a more pleasant work environment while meeting high environmental standards. The machine's drivetrain is built for durability and traction. Both wheeled and tracked models utilize a chain-drive system with four-wheel drive, ensuring high transmission efficiency and the robust capability to perform reliably even in the most challenging and muddy conditions. Furthermore, the independent left and right hydraulic travel systems provide abundant, dedicated power to each side, enhancing maneuverability and pushing force.

Key Advantages of Choosing the Rippa Mini Skid Steer

Choosing a Rippa mini skid steer offers several distinct advantages that translate directly to productivity and return on investment. The machine's core design is a major benefit, boasting a compact structure and powerful performance. This combination allows it to access tight spaces where larger equipment cannot go, while still providing the strength needed for heavy-duty tasks. The low-emission B&S XR2100 engine is a cornerstone of its efficiency, ensuring strong performance is not achieved at the expense of high fuel costs or excessive environmental impact.

The independent hydraulic systems for the left and right wheels or tracks provide superior control and ample power. This design allows for precise, zero-radius turning and excellent traction, enabling the machine to navigate confined and uneven terrain with ease. When paired with the standard speed mode adjustment, operators can seamlessly match the machine's power delivery to the specific task at hand, whether it requires fine, careful movements or maximum digging and lifting force. This synergy of compact design, intelligent controls, and robust systems makes the Rippa mini skid steer a highly adaptable and profitable asset.

Comprehensive Attachment Options for Mini Skid Steers

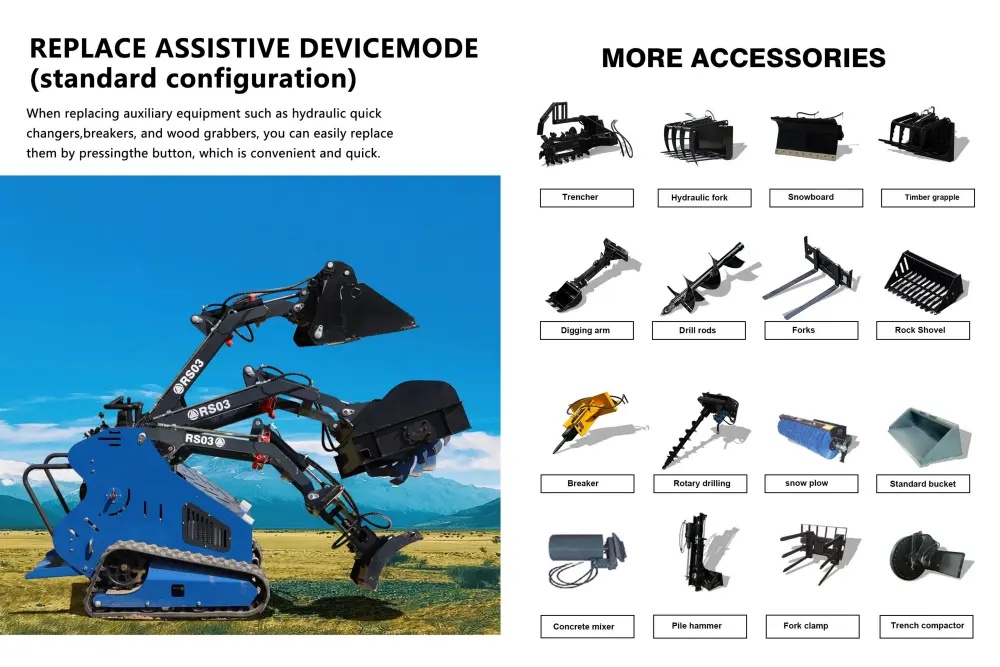

The true versatility of a mini skid steer loader is unlocked through its wide range of compatible attachments. The Rippa mini skid steer can transform from a simple loader into a multi-tool powerhouse, making it suitable for countless applications across landscaping, construction, agriculture, and property maintenance.

For excavation and earthmoving tasks, the essential standard bucket is just the beginning. Attachments like the trencher, digging arm, and rock bucket allow for precise digging and material handling. Grapples, such as the fork clamp and timber grapple, are perfect for moving logs, rocks, and irregular debris. Material handling is further enhanced with forks and a hydraulic fork for pallets and heavy items.

For breaking and drilling work, attachments like the concrete breaker, pile hammer, drill rod, and rotary drill expand the machine's capabilities into demolition and foundation tasks. The concrete mixer attachment enables on-site mixing of materials. Seasonal work is also covered with implements like the snow plow and snow pusher. Finally, for finishing work, the trench compactor attachment ensures backfilled trenches are properly compacted and stable.

Related News

Submitted successfully

We will contact you as soon as possible