snow plow for skid steer

Global Agent Recruitment

We are now recruiting agents worldwide!

Ideal for businesses and dealers – Start with just one unit for your overseas warehouse.

Tailored for construction projects – Wholesale only, not for retail.

Local inventory advantage – Warehouses near you ensure fast delivery and a full range of accessories.

24/7 customer support – Always here to assist you.

👉 Fill in your details, get a quick quote, and join us as our valued agent today!

Features and Costs of Skid Steer Loader Rock Hammers and Compact Track Loaders

In fields like construction, agriculture, and landscaping, skid steer loaders and compact track loaders are indispensable equipment due to their unparalleled versatility and compact size. Equipped with attachments like skid steer rock hammers, their applications are greatly expanded. This article will explore the performance of these powerful machines, starting with their product features and analyzing the cost components of a new skid steer loader, to help you make an informed purchasing decision.

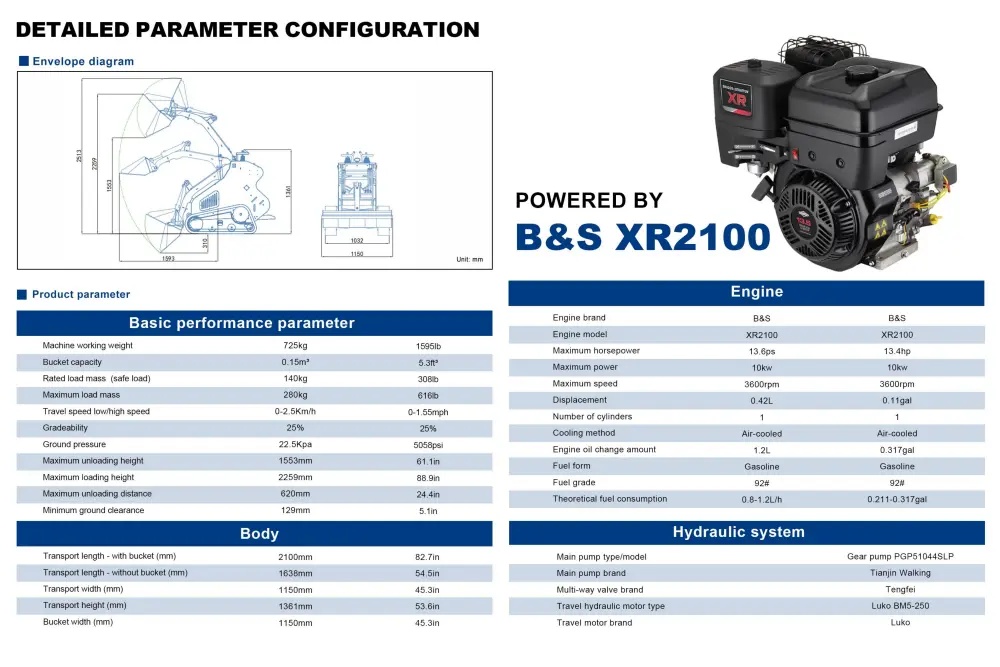

Efficient and Environmentally Friendly Power Core

The core of the equipment is its power system. Take the B&S XR2100 engine, for example. This engine exemplifies both high efficiency and environmental friendliness. Its low fuel consumption significantly reduces long-term operating costs, saving users considerable fuel expenses. Furthermore, the engine produces minimal vibration during operation, providing a more comfortable and less fatigue-prone working environment for the operator. Its low noise level not only enhances the operator experience but also makes it more suitable for use in residential areas or indoor environments with strict noise restrictions. This achieves a high level of environmental protection, in line with the development trends of modern construction machinery.

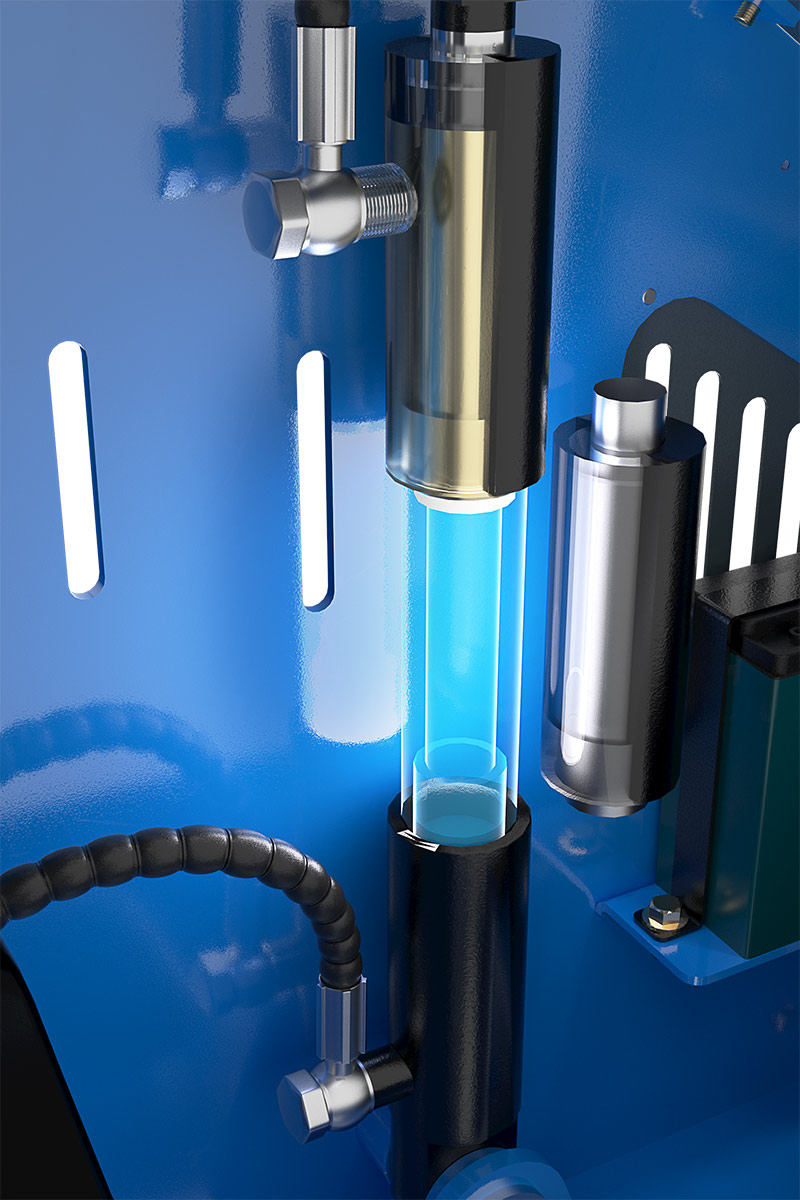

Durable Inverted Cylinder Design

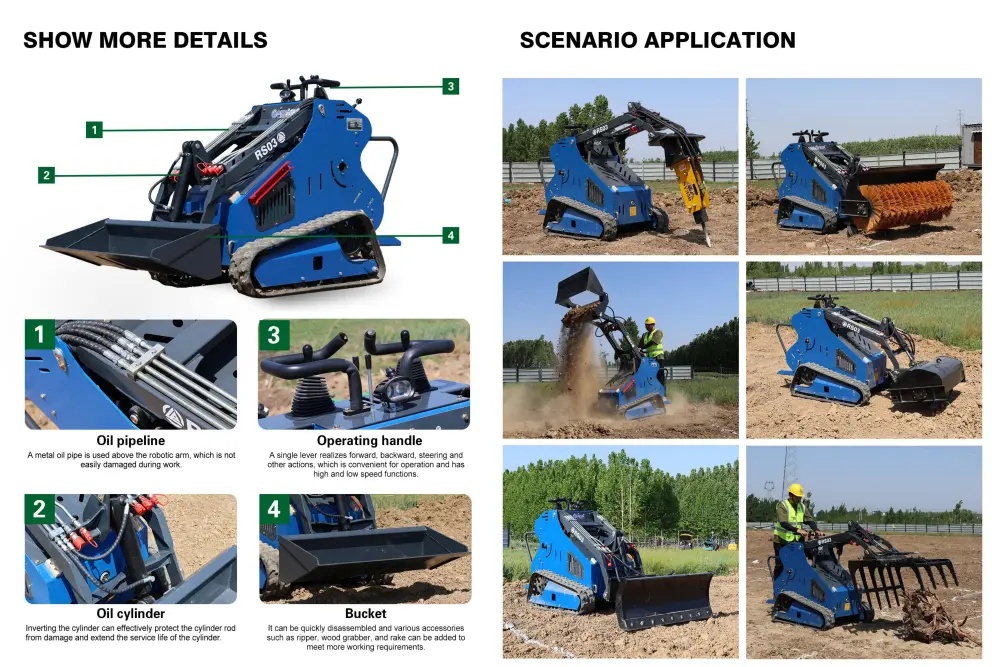

For high-strength attachments like skid-steer loader hammers, hydraulic system reliability is paramount. A key design feature is the inverted cylinder design. In standard cylinders, the piston rod is exposed and susceptible to impact from flying rocks and debris, which can cause scratches or damage, leading to seal failure and oil leakage. The inverted design, however, positions the cylinder body externally, effectively protecting the rod from damage. This significantly reduces downtime due to external impacts and significantly extends cylinder life, reducing overall maintenance costs and improving the return on investment for the equipment.

The true value of skid-steer and compact track loaders lies in their incredible versatility. Quick couplers allow operators to swap out a variety of attachments in minutes, transforming a single machine into a complete construction team. Besides the core skid-steer loader hammer for demolition and rock breaking, users can add a variety of accessories, such as hammers, rippers, log grapples, and rakes, to meet diverse workloads. For example, a bucket can be used for hauling, a forklift arm can handle pallets, a desilting bucket can be used for ditch cleaning, and a mower can be used for landscaping. This "one machine, multiple uses" capability greatly expands the equipment's applications and creates even greater value for users.

Submitted successfully

We will contact you as soon as possible