mini excavator size chart

Global Agent Recruitment

We are now recruiting agents worldwide!

Ideal for businesses and dealers – Start with just one unit for your overseas warehouse.

Tailored for construction projects – Wholesale only, not for retail.

Local inventory advantage – Warehouses near you ensure fast delivery and a full range of accessories.

24/7 customer support – Always here to assist you.

👉 Fill in your details, get a quick quote, and join us as our valued agent today!

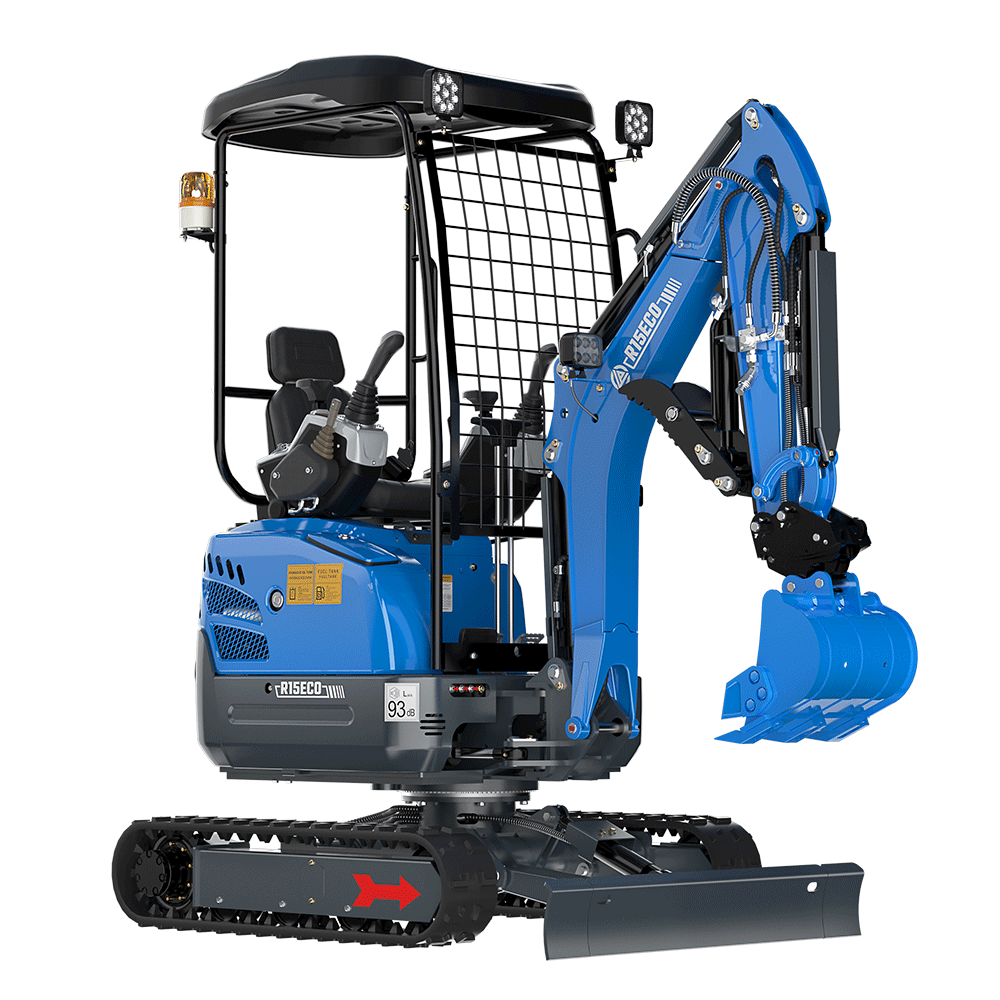

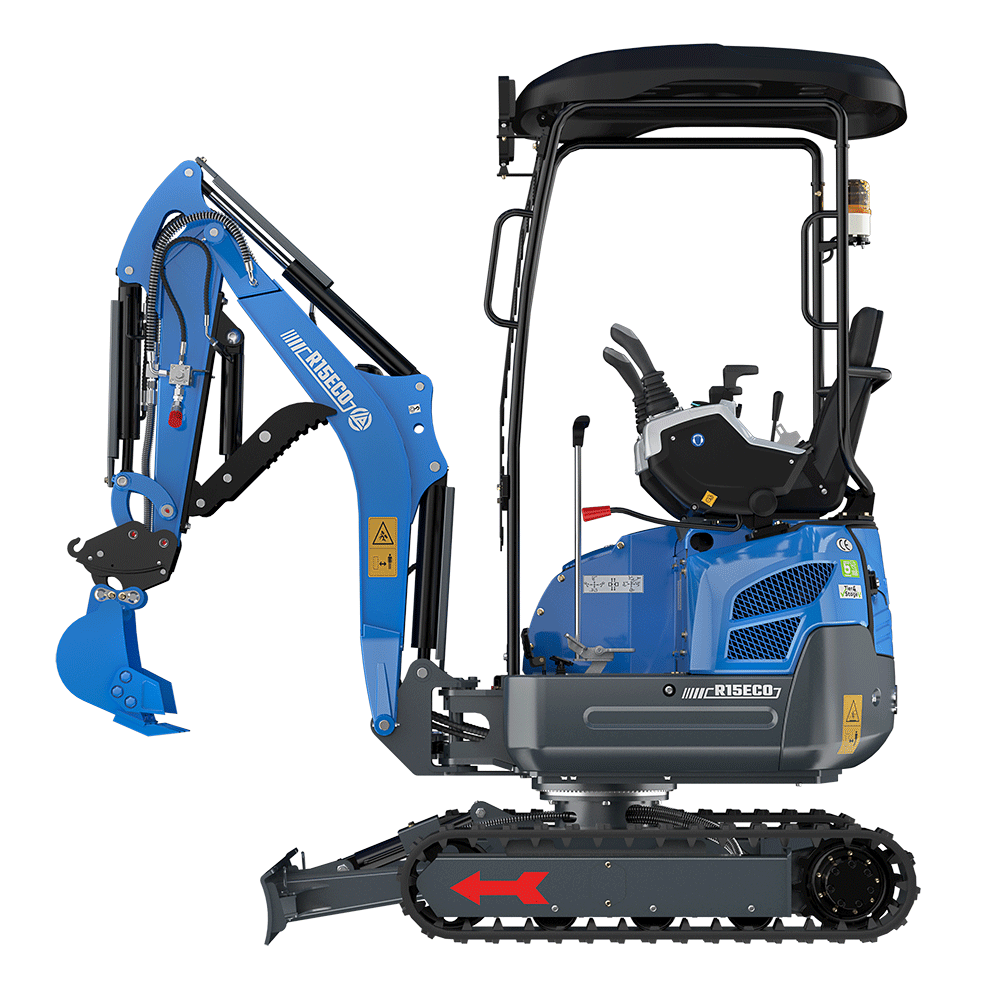

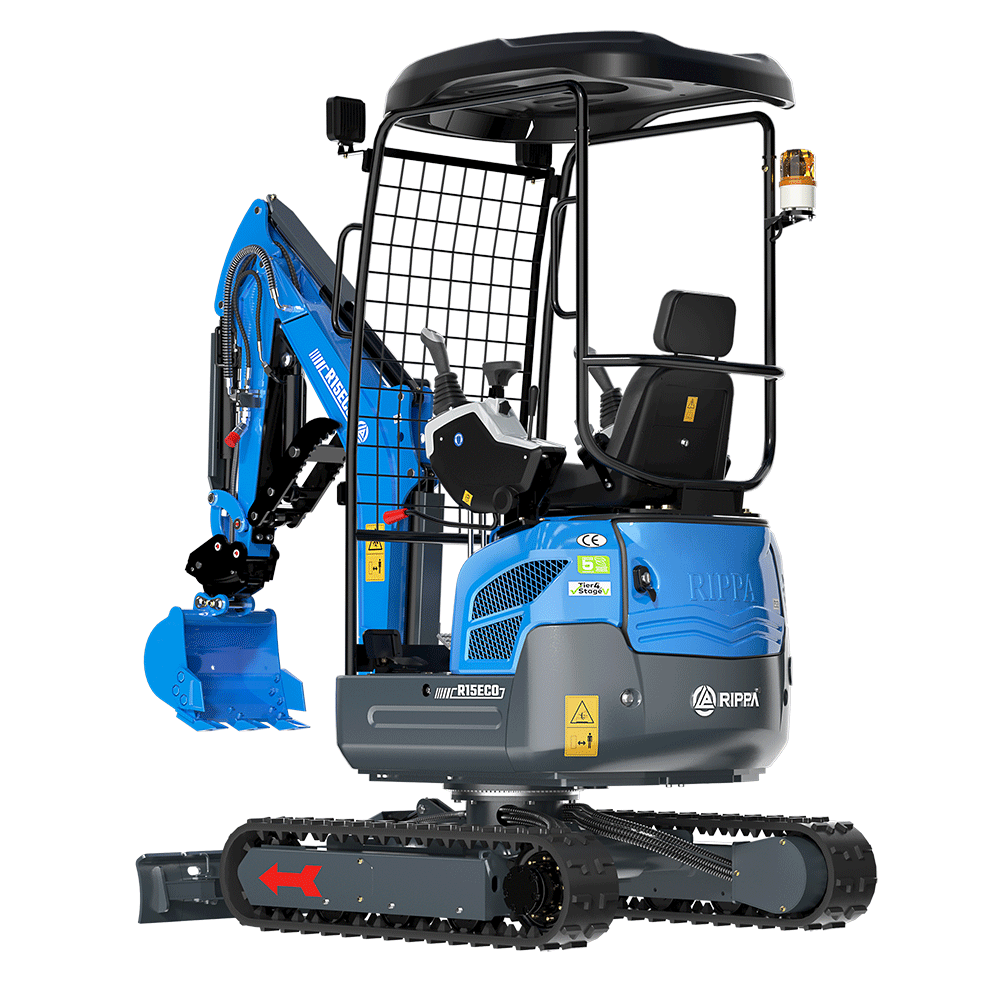

Advanced Hydraulic System Enhancements

The upgraded hydraulic quick coupler is designed with a dual mechanical safety lock controlled by a rocker switch. This system significantly improves safety and reliability during tool changes, ensuring that attachments remain securely fastened under heavy workloads. In addition, the hydraulic piping layout has been optimized, reducing friction and minimizing wear, which extends the overall lifespan of the excavator’s hydraulic components.

To improve performance in demanding applications, the machine is now equipped with four high-pressure breaker pipelines. This addition allows the excavator to handle powerful hydraulic attachments with greater efficiency. The joystick has also been upgraded to a dual-button design, enabling operators to switch between swing and deflection functions using the left joystick button. This ergonomic improvement reduces operator fatigue and allows for smoother control during precision tasks.

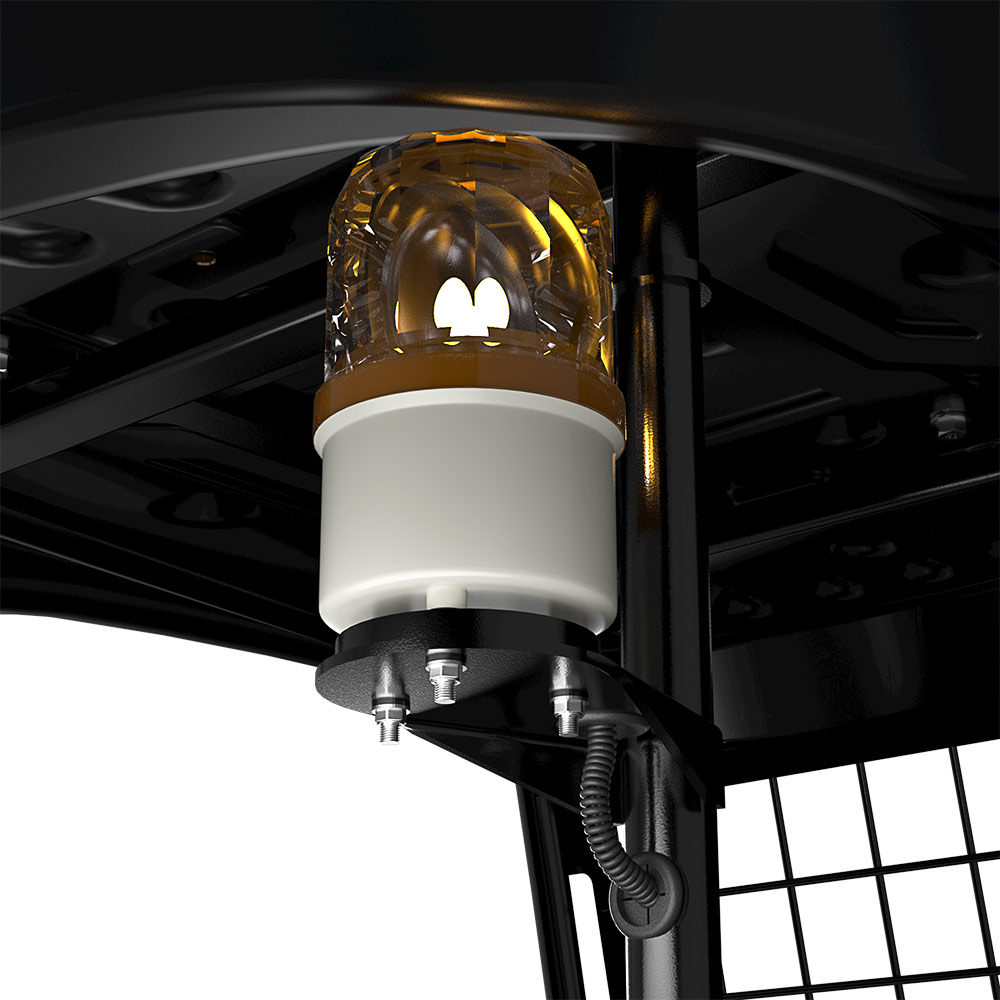

Another major enhancement is the introduction of a forward and reverse hand switch system. This flexibility allows operators to choose their preferred control orientation, improving adaptability and overall operator comfort. Furthermore, the machine now features a warning light mounted with a bolt-fixed base instead of a magnetic base. This upgrade ensures greater stability and visibility, even in high-vibration working conditions.

Operator Comfort and Structural Upgrades

The excavator has been upgraded to a full pilot control system, completely replacing mechanical controls. This transformation delivers smoother, more stable handling, significantly boosting operational efficiency. Alongside this, the routing of all hydraulic lines has been refined for cleaner layout and better accessibility, ensuring reduced maintenance downtime and improved overall performance.

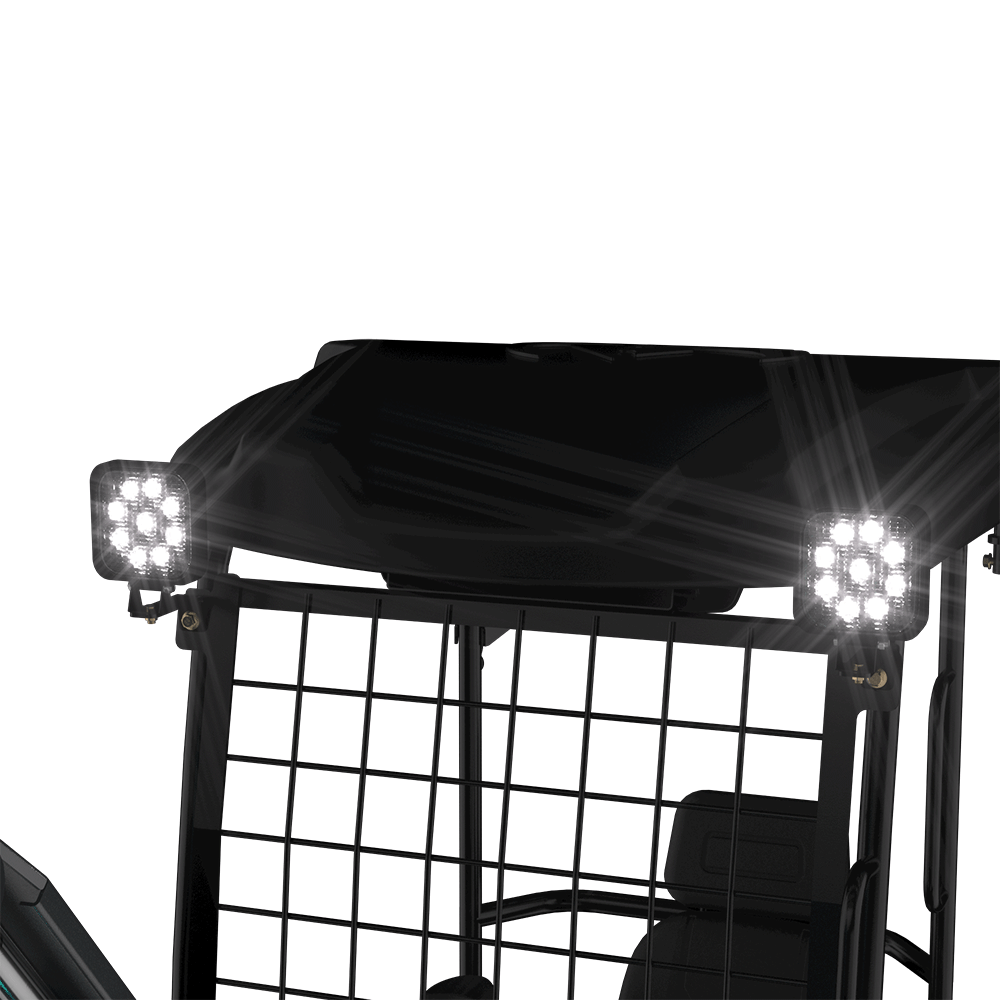

To improve safety and usability in low-light conditions, a roof-mounted front spotlight has been added, providing operators with better visibility during nighttime or tunnel operations. Inside the engine compartment, new heat insulation material has been installed to reduce cabin temperature and improve comfort during long working hours. The undercarriage motor now features a lifting point, making transportation and service handling easier and safer.

Durability and protection have also been upgraded. Hydraulic pipes are now equipped with protective grease nipple covers, using pointed grease nipples for more secure lubrication. The ignition switch is protected by a dedicated cover, safeguarding it against dust, debris, and accidental damage. To enhance operator comfort, non-slip rubber mats have been installed inside the cabin, providing both safety and noise reduction during operation.

Related News

Submitted successfully

We will contact you as soon as possible