excavator services near me

Global Agent Recruitment

We are now recruiting agents worldwide!

Ideal for businesses and dealers – Start with just one unit for your overseas warehouse.

Tailored for construction projects – Wholesale only, not for retail.

Local inventory advantage – Warehouses near you ensure fast delivery and a full range of accessories.

24/7 customer support – Always here to assist you.

👉 Fill in your details, get a quick quote, and join us as our valued agent today!

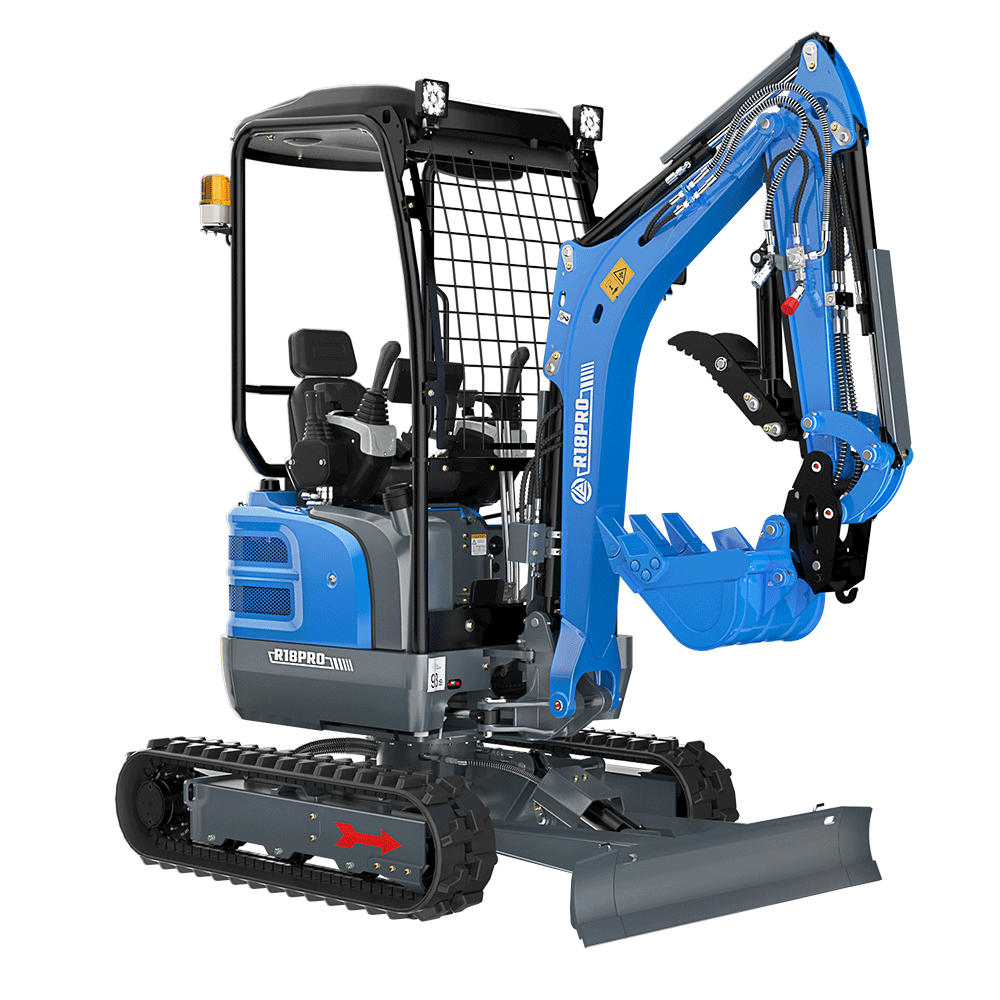

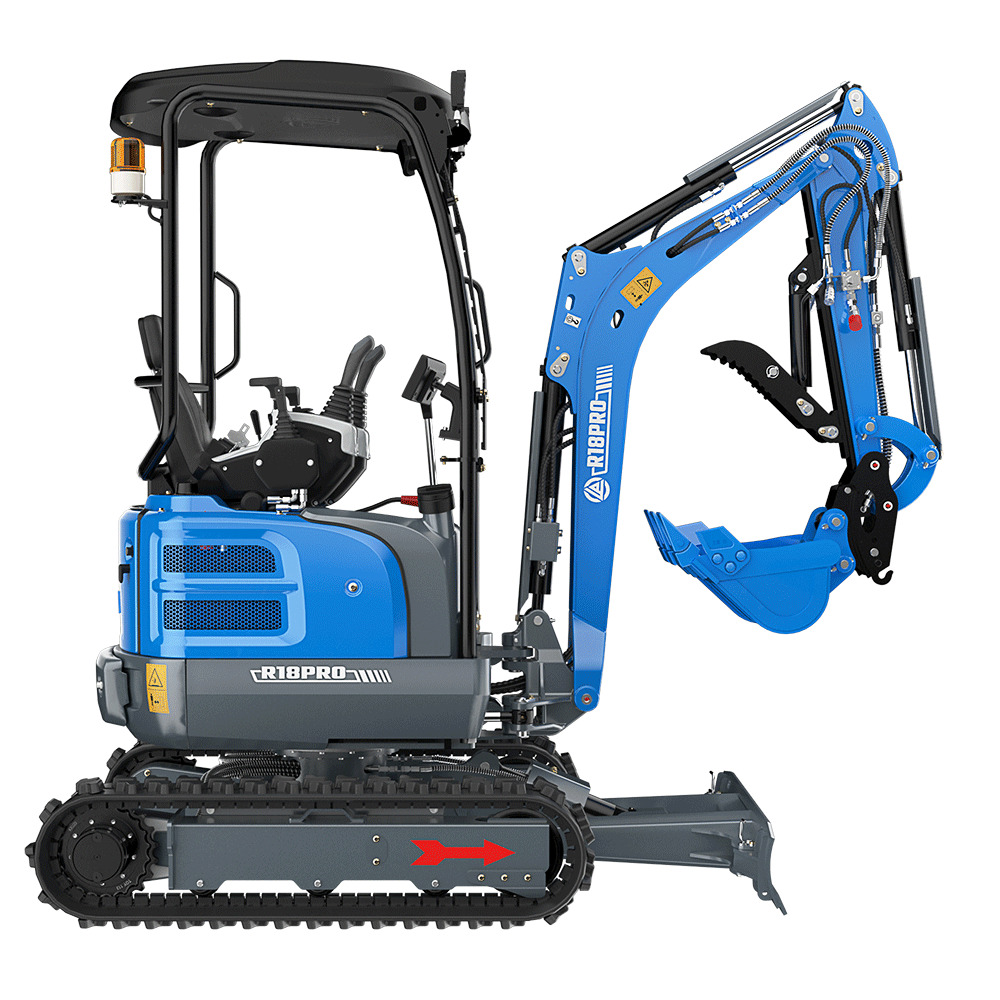

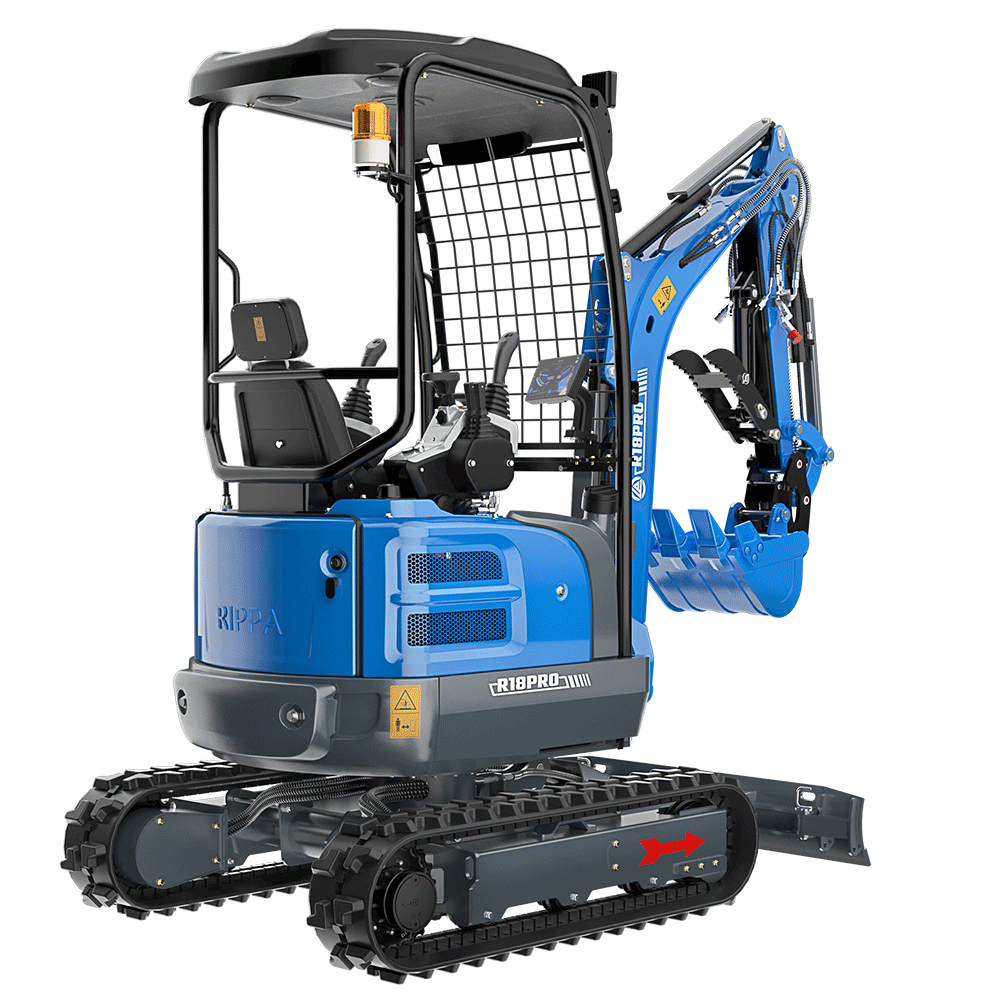

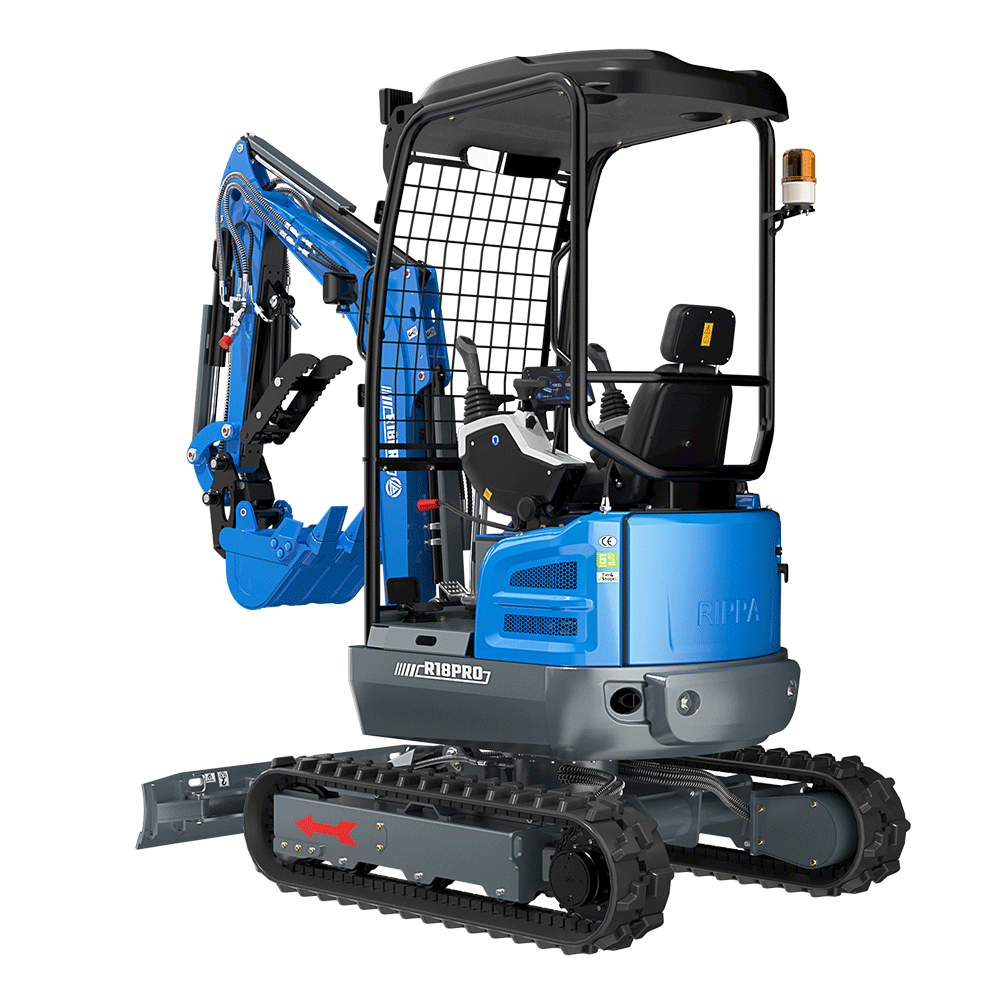

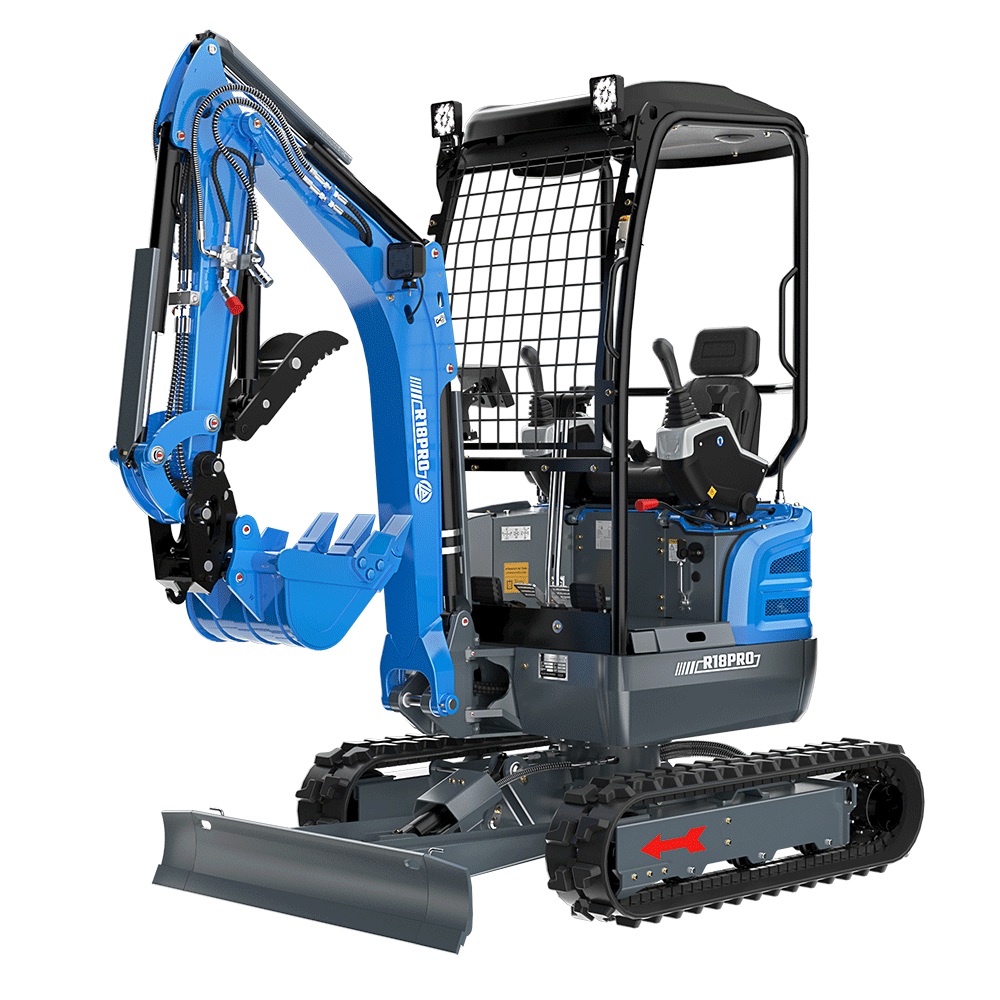

Hydraulic System Innovations

The upgraded hydraulic quick coupler is now controlled by a rocker switch with dual mechanical safety locks. This feature greatly enhances the reliability of attachment changes, ensuring tools remain firmly secured under heavy-duty operation. By reducing the risk of accidental detachment, the excavator provides higher levels of operational safety and efficiency in demanding job sites.

The hydraulic piping layout has been comprehensively optimized to improve durability and reduce friction losses. This refined routing not only minimizes maintenance frequency but also enhances hydraulic flow efficiency, translating into smoother machine performance. In addition, the system now supports four high-pressure breaker pipelines along with a reserved return line for mower attachments. This makes the machine more versatile, enabling it to adapt to multiple working environments with different tool requirements.

Operator control has been significantly improved with a new dual-button joystick design. This setup allows deflection and swing functions to be switched through the left joystick button, giving operators more intuitive handling. A forward and reverse hand switch has also been introduced, allowing operators to select their preferred control mode. These improvements are tailored to reduce fatigue and increase precision during long working hours.

A newly added explosion-proof valve plays a critical role in preventing sudden boom descent in the event of hydraulic hose rupture. This safety measure greatly reduces the risk of accidents, ensuring both operator protection and extended component life. Meanwhile, the warning light has been upgraded from a magnetic base to a bolt-mounted design, offering better stability in high-vibration environments and improving visibility on construction sites.

Structural Upgrades and Safety Enhancements

The overall hydraulic line routing has been redesigned and upgraded, resulting in a cleaner layout that improves both serviceability and system reliability. To protect lubrication points, the hydraulic cylinders are now equipped with protective grease nipple covers. Pointed grease nipples have been adopted for more effective lubrication, helping to reduce wear and extend component service life.

Inside the engine compartment, heat insulation cotton has been installed to regulate cabin temperature and reduce noise levels. This addition creates a more comfortable working environment for operators, especially during long shifts in hot weather conditions. To further improve durability, the ignition key port has been fitted with a rubber protective cover, shielding it from dust, moisture, and accidental damage.

The machine now features rubber non-slip mats across the operator’s cabin floor. These mats provide superior grip, reduce vibrations, and improve operator comfort by minimizing fatigue during extended operations. Together with the other enhancements, they contribute to a safer, more stable, and more ergonomic working environment, allowing the excavator to deliver higher productivity and reliability on construction projects.

Related News

Submitted successfully

We will contact you as soon as possible