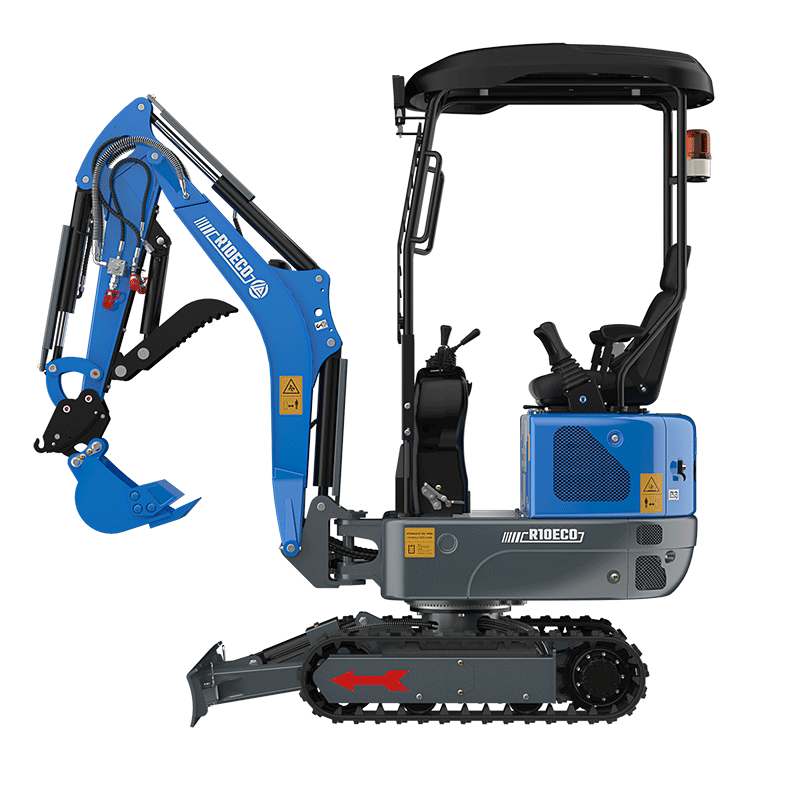

mini excavator tracks

Global Agent Recruitment

CE, EPA, Euro5, and TUV certified.

We are now recruiting agents worldwide!

Ideal for businesses and dealers – Start with just one unit for your overseas warehouse.

Tailored for construction projects – Wholesale only, not for retail.

Local inventory advantage – Warehouses near you ensure fast delivery and a full range of accessories.

24/7 customer support – Always here to assist you.

👉 Fill in your details, get a quick quote, and join us as our valued agent today!

Practical Uses of Mini Excavators for Better Work Efficiency

Mini excavators are essential compact machines widely used across construction, landscaping, agriculture, municipal engineering and road maintenance projects. Their small body structure and powerful hydraulic system allow them to operate efficiently even in narrow and confined working environments where large excavators cannot reach. These machines are capable of digging trenches, breaking concrete, loading materials, lifting pipes and clearing debris with high precision and speed.

In addition to their versatility, mini excavators also improve work efficiency by reducing manual labor. With flexible boom movements and 360° rotation, operators can finish continuous digging, loading and dumping tasks without repositioning the machine repeatedly. This reduces time loss during operations and increases productivity on job sites. Their adjustable working attachments make them ideal for seasonal applications such as planting trees, laying irrigation systems, and even small demolition work, which greatly benefits small contractors and private landowners.

Mini excavators also deliver excellent fuel efficiency thanks to their low engine consumption and optimized hydraulic systems. This advantage helps companies reduce operational and maintenance costs while maintaining strong digging power. Whether used in cities, farms or rural areas, mini excavators provide high return on investment due to their lower transportation cost, flexible movement and multi-functionality.

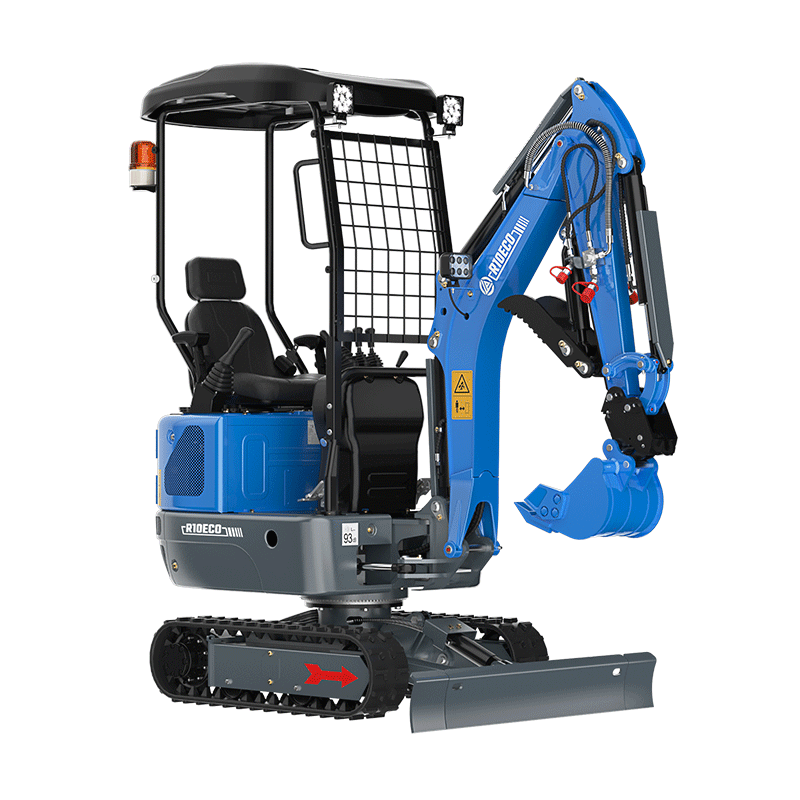

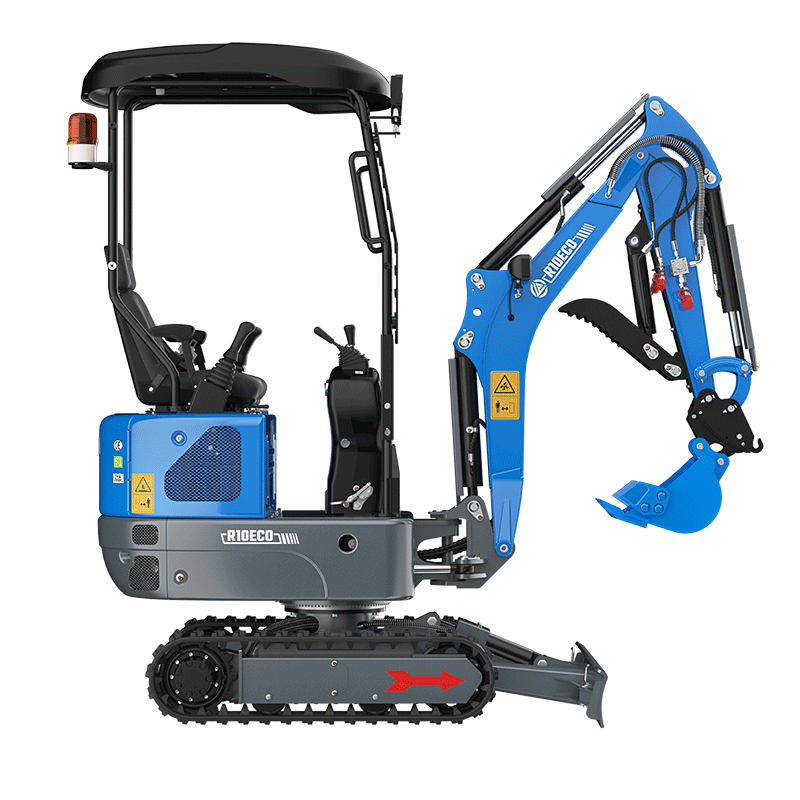

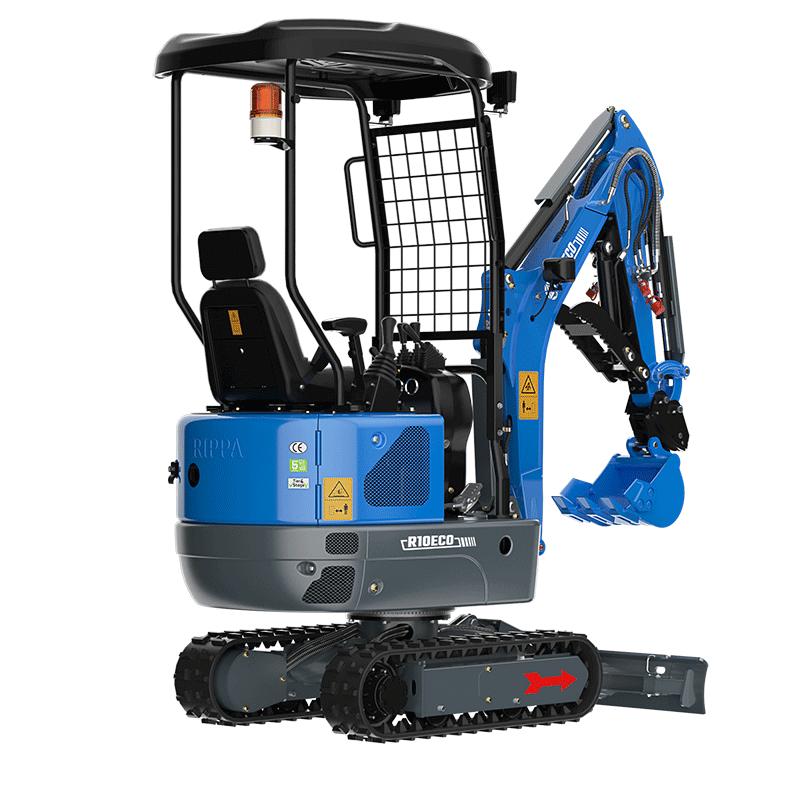

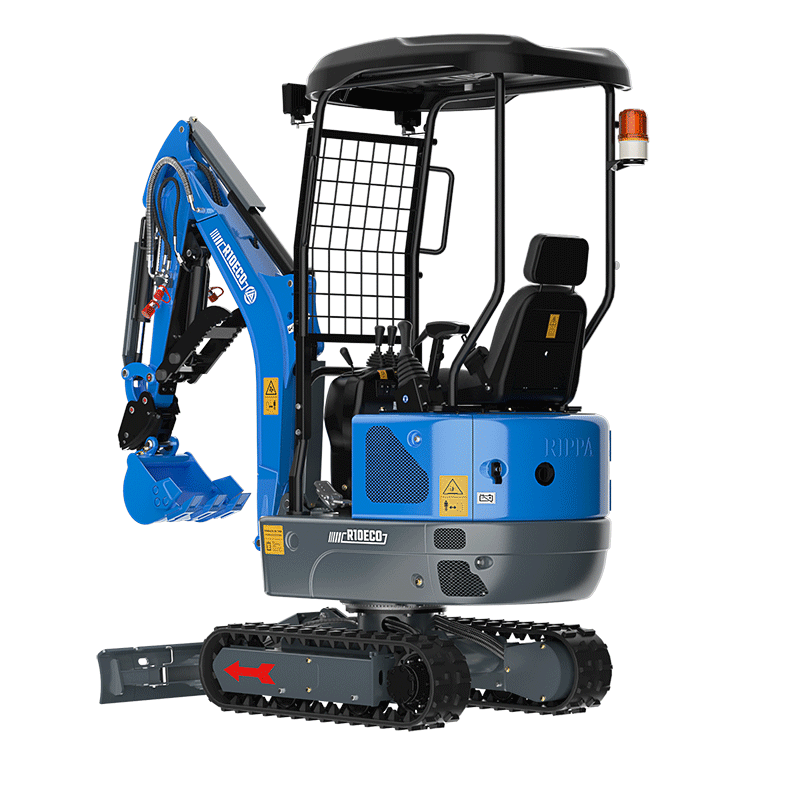

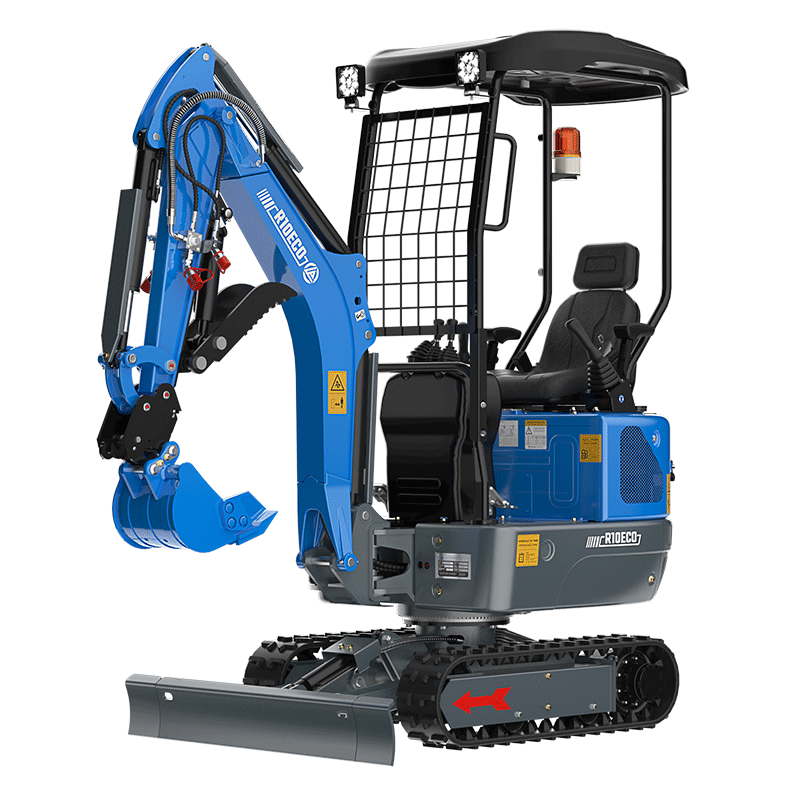

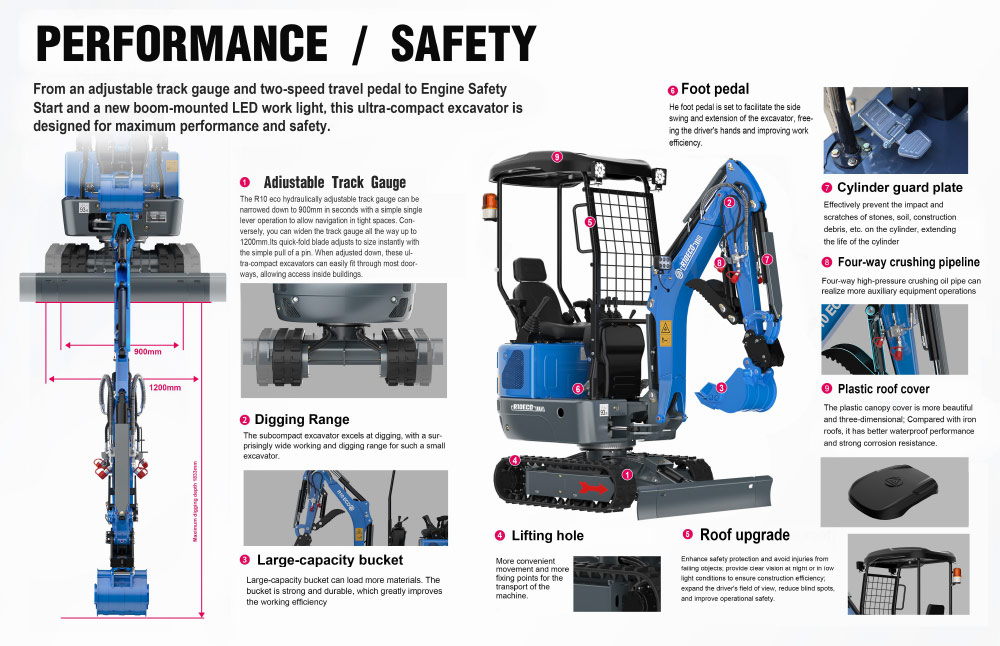

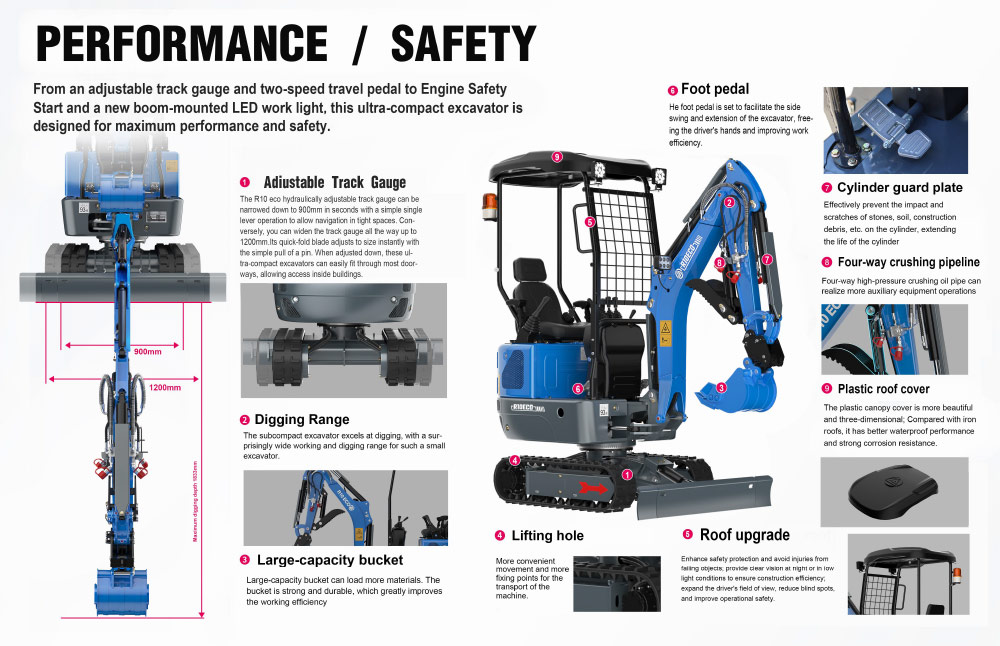

Structural Advantages of Rippa Mini Excavators

Rippa Mini Excavators stand out in the global market due to their professional engineering design, durability and user-friendly functionality. One of the major structural upgrades is the reinforced canopy equipped with a protective guard mesh. This enhances operator safety in environments where stones, wood or construction debris may fall during operation. To support night work and low-visibility environments, additional front headlights are installed to improve lighting performance and ensure accurate digging at all times. Rear-view mirrors are also included to increase operator awareness and prevent collisions when moving or rotating in tight work areas.

To further enhance durability, the top cover of the canopy is upgraded from metal to a high-strength plastic material. This offers better resistance against corrosion, sun exposure and vibration, extending the machine’s service life. The upper frame is upgraded to a full-steel plate turntable, improving overall body rigidity and reducing deformation under heavy loads. This improves digging stability and supports long-term, high-intensity operation.

For transportation convenience, lifting holes are added around the travel motor section of the lower chassis. These lifting points make it easier to load the machine using cranes or forklifts, reducing handling risks. This is especially beneficial for export customers, rental companies and contractors who frequently move machines between different job sites.

Maintenance-Friendly Design and Protection Features

Daily maintenance is critical to keeping mini excavators operating at full performance, and Rippa has simplified this process through smart design. The excavator uses pointed grease nipples, making it easier for operators to apply grease neatly and efficiently. These are positioned at key joints to reduce friction and prevent premature wear.

To prevent damage during digging, protective blocks are added around the grease nipples. These prevent stones and soil from striking the lubrication points during trenching or breaking tasks. The addition of U-shaped block guards is another innovative upgrade, making it easy to remove mud and dirt that might otherwise accumulate around the joints. This design reduces the time required for cleaning and ensures long-term reliability.

Other service components like filters, oil inlets and hydraulic inspection ports are positioned where they can be easily accessed without removing large panels. This saves maintenance time and ensures that machines remain in good working condition, reducing downtime for users.

Precision Counterweight System for Stability and Efficiency

One of the standout engineering advantages of Rippa mini excavators is the balanced counterweight system. The counterweight is carefully calculated to balance the boom and arm working torque, which significantly improves stability when lifting heavy materials or digging deep trenches. A well-designed counterweight allows the excavator to operate safely on sloped terrain or uneven surfaces without the risk of tipping.

This counterweight system not only enhances safety but also increases operational efficiency by giving the operator better control and smoother performance. With improved balance, the excavator can extend its working reach and handle larger attachments without compromising stability. This makes it suitable for a wider variety of jobs, expanding its working capability in real-world applications.

Furthermore, by reducing vibration and body sway during rotation, the counterweight helps protect the main frame and hydraulic components from stress damage. This results in longer machine service life and lower maintenance costs. The counterweight system is an essential part of Rippa’s engineering approach to deliver high efficiency, safety and multipurpose operation in compact excavators.

Related News

Submitted successfully

We will contact you as soon as possible