new mini excavator for sale

Global Agent Recruitment

CE, EPA, Euro5, and TUV certified.

We are now recruiting agents worldwide!

Ideal for businesses and dealers – Start with just one unit for your overseas warehouse.

Tailored for construction projects – Wholesale only, not for retail.

Local inventory advantage – Warehouses near you ensure fast delivery and a full range of accessories.

24/7 customer support – Always here to assist you.

👉 Fill in your details, get a quick quote, and join us as our valued agent today!

Enhanced Control System Improves Mini Excavator Work Efficiency

Mini excavators are widely used in construction, agriculture, landscaping, and utilities for tasks such as trenching, digging, grading, and demolition. Their compact size allows them to operate efficiently in narrow sites where larger machinery cannot enter. With advanced hydraulic systems and precise control, mini excavators significantly improve project productivity while reducing labor intensity. Many contractors choose mini excavators because they offer exceptional maneuverability, low fuel consumption, and easy transportation to job sites.

Rippa mini excavators are engineered to maximize efficiency in real working conditions. Equipped with advanced hydraulic flow systems, they deliver smooth power output and fast response speed. Whether working on pipelines, foundation digging, or farm trenching, they provide stable performance and consistent digging force. Compared with manual labor, a mini excavator can increase working efficiency by up to five times while ensuring precision and safety in complex tasks.

Rippa Mini Excavator Joystick and Hydraulic Advantages

Rippa mini excavators are designed with operator-friendly controls that enhance precision and productivity. The left and right joysticks are each equipped with two functional buttons located at the top front of the handle. These buttons control key auxiliary functions such as boom swing or quick hitch operation. With an ergonomic layout, the joysticks are easy to operate and reduce hand fatigue during long working hours.

Unlike simple on/off control systems, Rippa joysticks use a proportional hydraulic control mechanism. The hydraulic flow rate changes according to joystick displacement, allowing operators to adjust motion speed and digging power smoothly. Light joystick input triggers slow and delicate actions, ideal for fine grading or pipeline work, while deeper input delivers stronger, faster movements for heavy digging. This stepless speed control not only increases operational accuracy but also protects the hydraulic system from unnecessary stress.

The joystick assembly is designed with high-grade sealing and dust-proof protection. It also offers waterproof performance with a high IP rating, making the Rippa mini excavator reliable in harsh working environments such as muddy farmland, dusty construction sites, and rainy outdoor projects. Whether in freezing winters or hot summers, the control system remains stable and responsive.

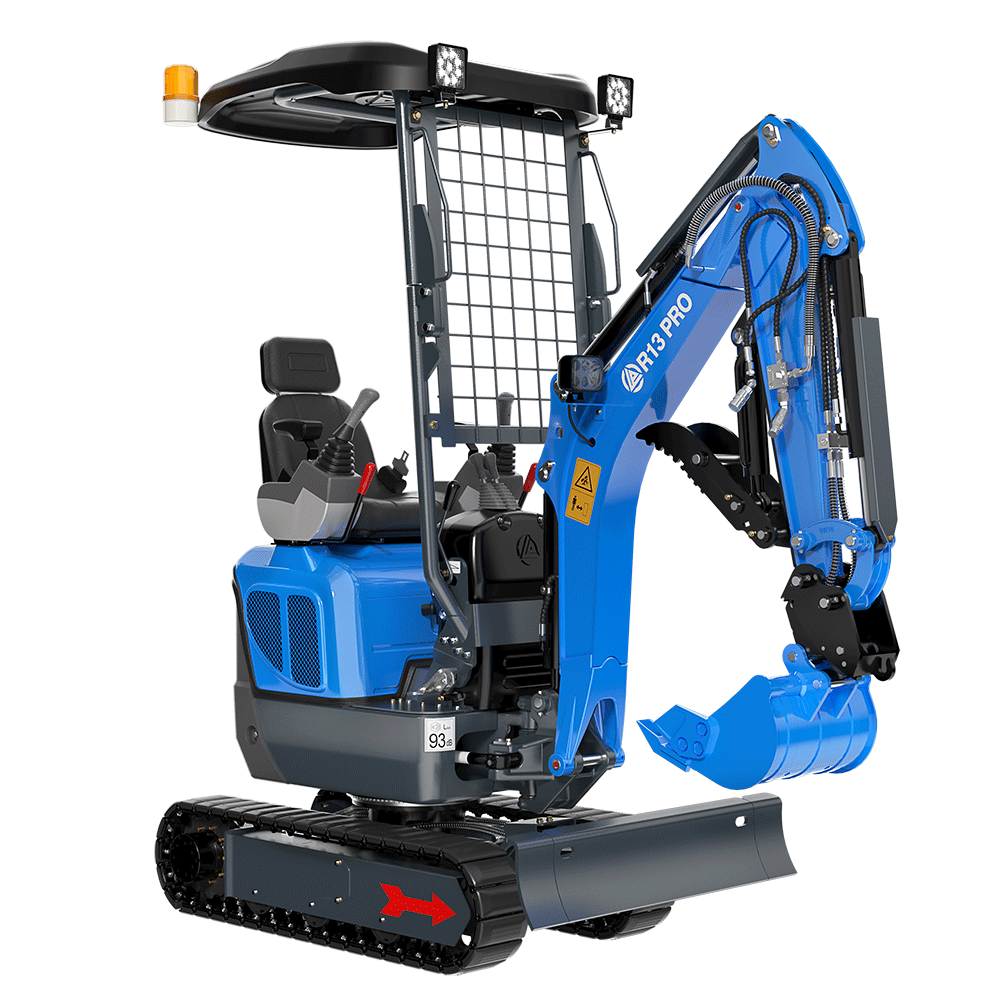

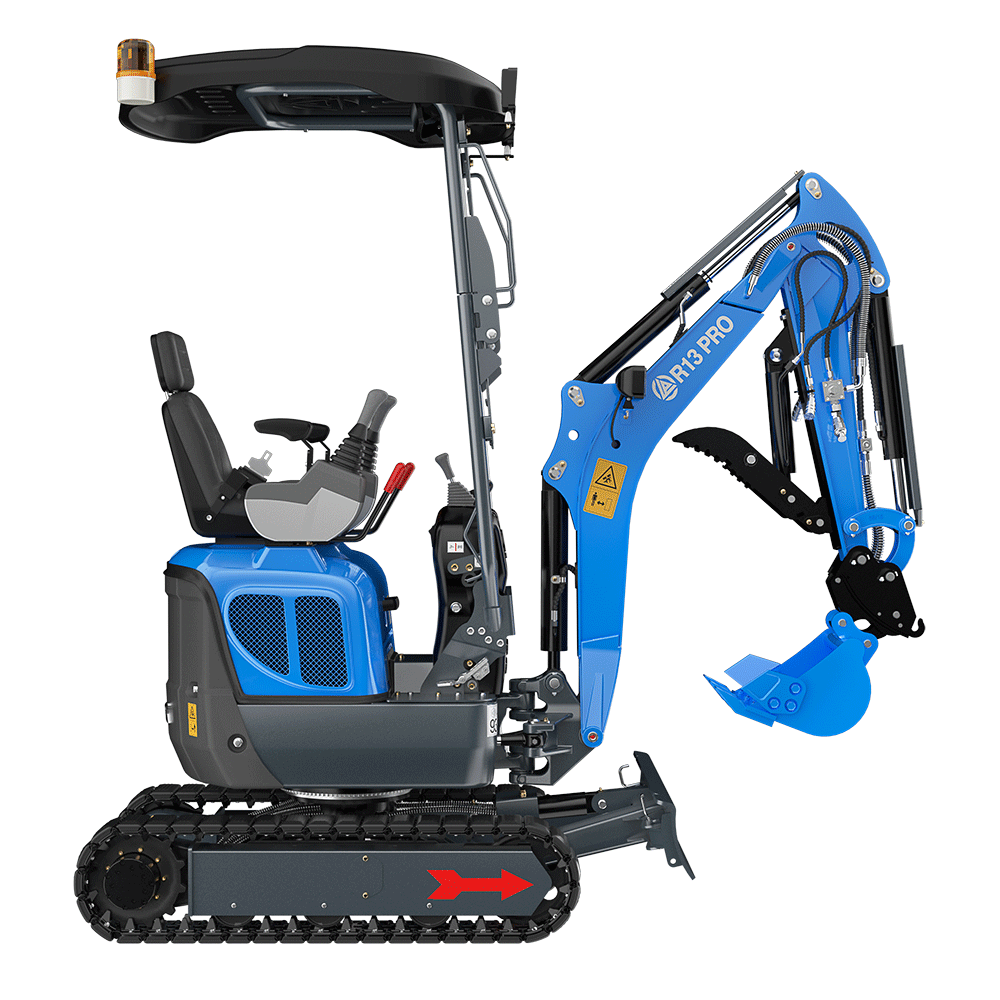

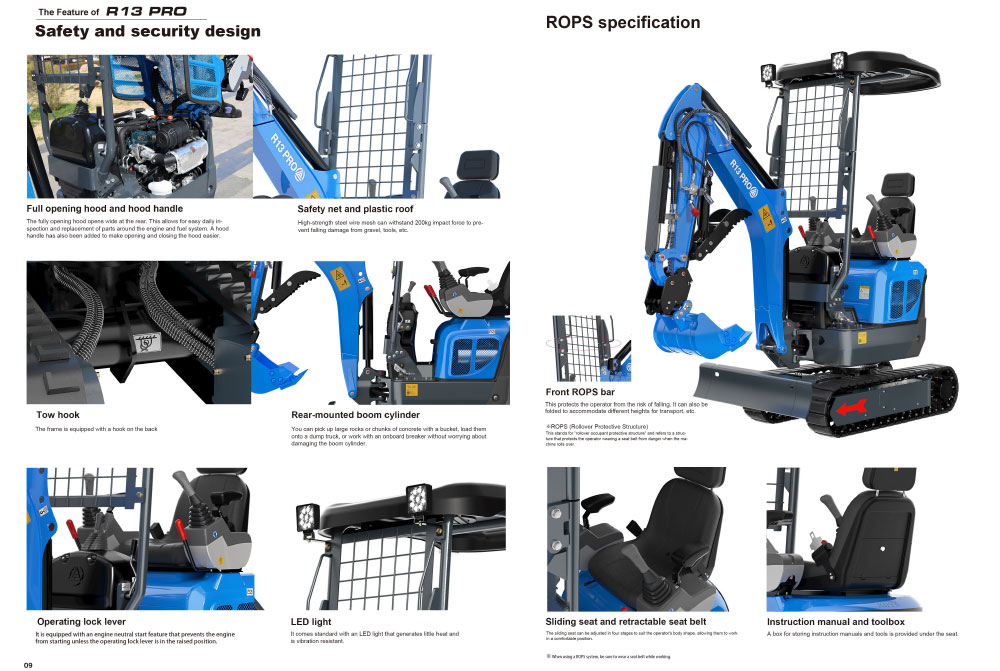

Safe and Practical Rippa Mini Excavator Canopy Design

Safety is a top priority in construction machinery, and Rippa mini excavators are built with enhanced operator protection. The canopy is upgraded with a durable plastic top cover that provides excellent insulation, impact resistance, and corrosion protection. This material helps reduce the risk of electric hazards and improves long-term durability under outdoor exposure.

To prevent falling objects from injuring the operator, Rippa has added a protective mesh at the front area of the canopy. This safety structure reduces workplace injuries, especially in construction zones where stones, debris, or branches may fall during operation. The canopy structure is suitable for multiple working environments such as mining, municipal engineering, forestry, and agricultural work.

For safer night operations, the canopy is equipped with high-position LED working lights. These lights illuminate both the front field of vision and the digging area, preventing operational mistakes caused by poor visibility. Unlike traditional headlamps that produce strong contrast and shadows, the canopy lights provide even illumination, reducing eye fatigue during long shifts. Additionally, a rear warning light is included to enhance visibility in crowded job sites. This clear rear alert system protects both personnel and surrounding vehicles. A rear-view mirror is installed to reduce the operator’s need to frequently turn around, improving safety and reducing neck fatigue.

Related News

Submitted successfully

We will contact you as soon as possible