Master the Toughest Jobs with the RIPPA R22 PRO Mini Excavator

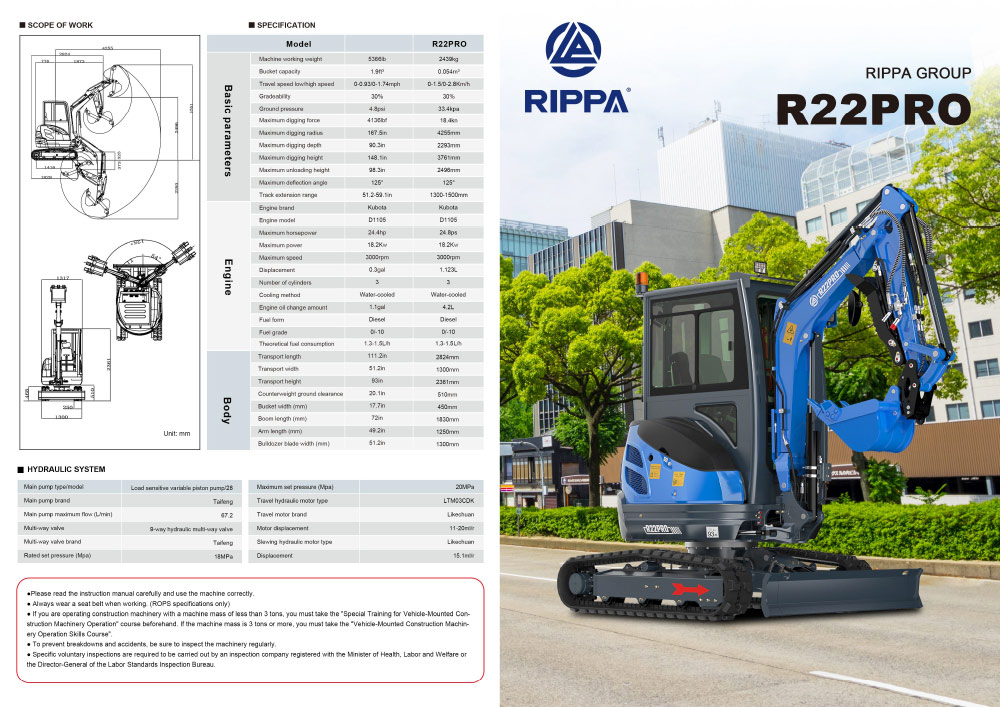

The RIPPA R22 PRO is engineered to deliver high-tier performance in a compact 2.5-ton package, rivaling the power of much larger 3-ton machines. At its heart lies a Kubota D1105 water-cooled diesel engine, providing a robust 24.8 horsepower (18.2 Kw) to handle demanding excavation tasks with ease. This environmentally friendly powerhouse is fully compliant with both Euro V and U.S. EPA emission standards, ensuring that your projects meet modern environmental regulations without sacrificing torque or reliability.

Efficiency is further enhanced by the advanced NEW-HMS hydraulic system, which utilizes a sophisticated three-pump configuration. This design assigns independent pumps to the boom, arm, and swing functions, allowing for the simultaneous operation of four different movements without a drop in speed or power. Whether you are leveling a site or digging a deep trench, the load-sensitive variable piston pump ensures that hydraulic pressure is distributed exactly where it is needed, resulting in smooth, precise, and lightning-fast front movements.

Built for longevity, the R22 PRO features a reinforced front end, including cast steel components at the boom root, swing pivot, and travel motor support. These heavy-duty materials are specifically chosen to withstand the intense stresses of daily construction work. Additionally, the undercarriage is equipped with high-quality engineering rubber tracks in a herringbone pattern, which can be swapped for wear-resistant steel tracks depending on the terrain, providing exceptional stability and traction in any environment.

Unmatched Versatility and Precision Engineering

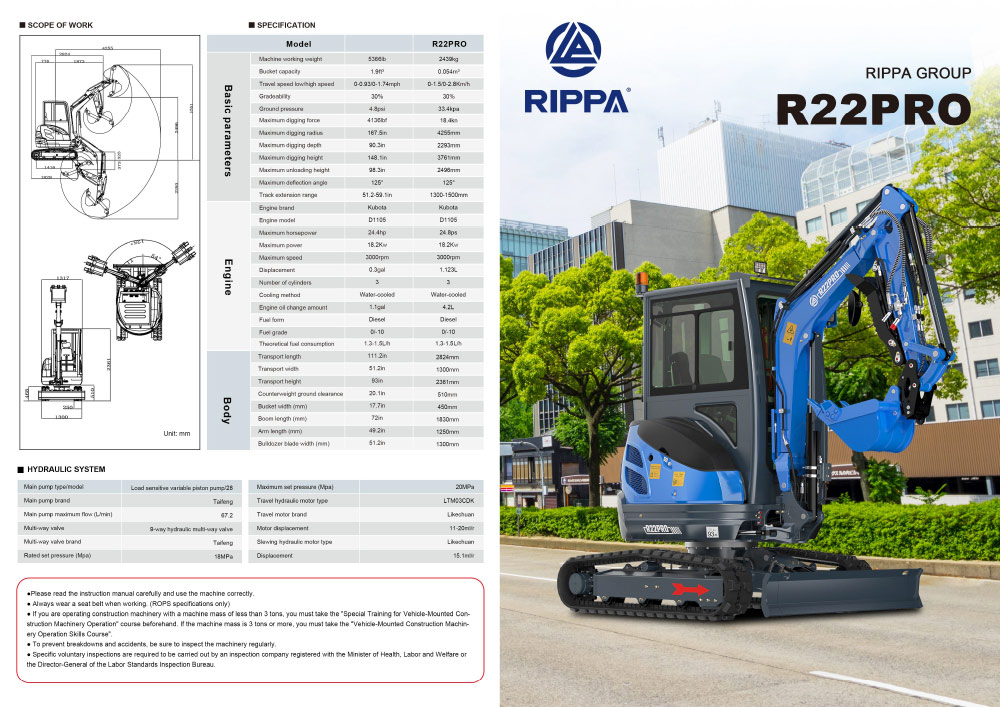

Adaptability is a core strength of the R22 PRO, highlighted by its optional variable leg specifications. The machine can reduce its track width to just 1300mm for navigating narrow access roads and tight workspaces, then expand to 1500mm during operation to maximize stability and digging performance. This flexibility, combined with a maximum digging depth of 90.3 inches and a digging radius of 167.5 inches, allows operators to take on a wide variety of landscaping, utility, and construction projects that would otherwise be inaccessible.

The R22 PRO is designed as a multi-functional tool carrier, featuring a high-flow service port compatible with diverse attachments like hydraulic breakers. For those looking to expand into vegetation management, the machine includes a dedicated lawn mower return line reservation, making the future addition of auxiliary mowing equipment a simple process. Furthermore, a hand switching valve allows operators to easily toggle between ISO and SAE operating modes, ensuring that the excavator can be customized to the pilot’s preferred control style for stress-free operation.

Safety remains paramount throughout the machine's design, featuring ROPS (Roll Over Protective Structure) and TOPS (Tip-Over Protective Structure) certified cabs. To protect against hydraulic failure, the R22 PRO is equipped with explosion-proof valves that prevent the machine from losing control if a pipeline is compromised under high pressure. Even the smallest details are considered, such as the grease fitting protection and U-shaped stops that prevent damage to the grease nozzles during operation while making mud cleanup significantly easier.

Superior Operator Comfort and Intelligent Control

Operating the R22 PRO is a premium experience thanks to a spacious, driver-centered cab designed for long hours on the job. The cockpit is fitted with a versatile shock-absorbing seat featuring adjustable armrests, headrests, and backrest angles to accommodate operators of all sizes. Generous foot space and non-slip rubber floor mats ensure a stable and comfortable environment, while the integrated air conditioning and heater systems maintain a perfect temperature regardless of extreme summer heat or mid-winter cold.

Modern technology is integrated through an intelligent large-screen display that serves as the command center for the machine. This digital interface provides real-time monitoring of all essential operating parameters and uses clear error codes and warning lights to alert the operator to any abnormalities in the hydraulic, charging, or cooling systems. This proactive feedback loop helps prevent minor issues from becoming costly repairs, allowing the operator to maintain focus on the task at hand.

Maintenance on the R22 PRO is designed to be tool-free and lightning-fast. The rear and right-side engine bonnets open wide, providing immediate access to the fuel system, air filter, and water tank for daily inspections. For more intensive overhauls, the engine covers can be fully disassembled in minutes, and the hydraulic maintenance points are centrally located on the right side of the machine. This focus on "smart maintenance" ensures that the R22 PRO spends more time on the job site and less time in the shop.