High-Performance Engineering and Core Specifications

The RIPPA R32 PRO is a powerhouse in the compact excavator category, meticulously engineered to bridge the gap between agility and heavy-duty capability. At its core, the machine is powered by a Kubota D1105 water-cooled diesel engine, a 3-cylinder unit that delivers a maximum of 24.8 horsepower (24.8 ps / 18.2 Kw). This engine is specifically selected for its ability to provide abundant torque while remaining environmentally friendly, fully complying with both the European Stage V and U.S. EPA exhaust emission standards. With a displacement of 1.123L and a maximum speed of 3000 rpm, this engine ensures the excavator can handle rigorous workloads with low noise and high fuel efficiency, typically consuming only 1.3 to 1.5 liters per hour.

The hydraulic heart of the R32 PRO is equally impressive, featuring a load-sensitive variable piston pump system. This advanced "NEW-HMS" hydraulic configuration utilizes a 3-pump system that assigns independent power to the boom, arm, and swing functions. This allows for simultaneous operation of four different movements—bucket, boom, arm, and rotation—without compromising speed or precision. The system operates at a rated set pressure of 18MPa and a maximum pressure of 20MPa, supported by a 9-way hydraulic multi-way valve that provides a wide control range for even the most demanding tasks.

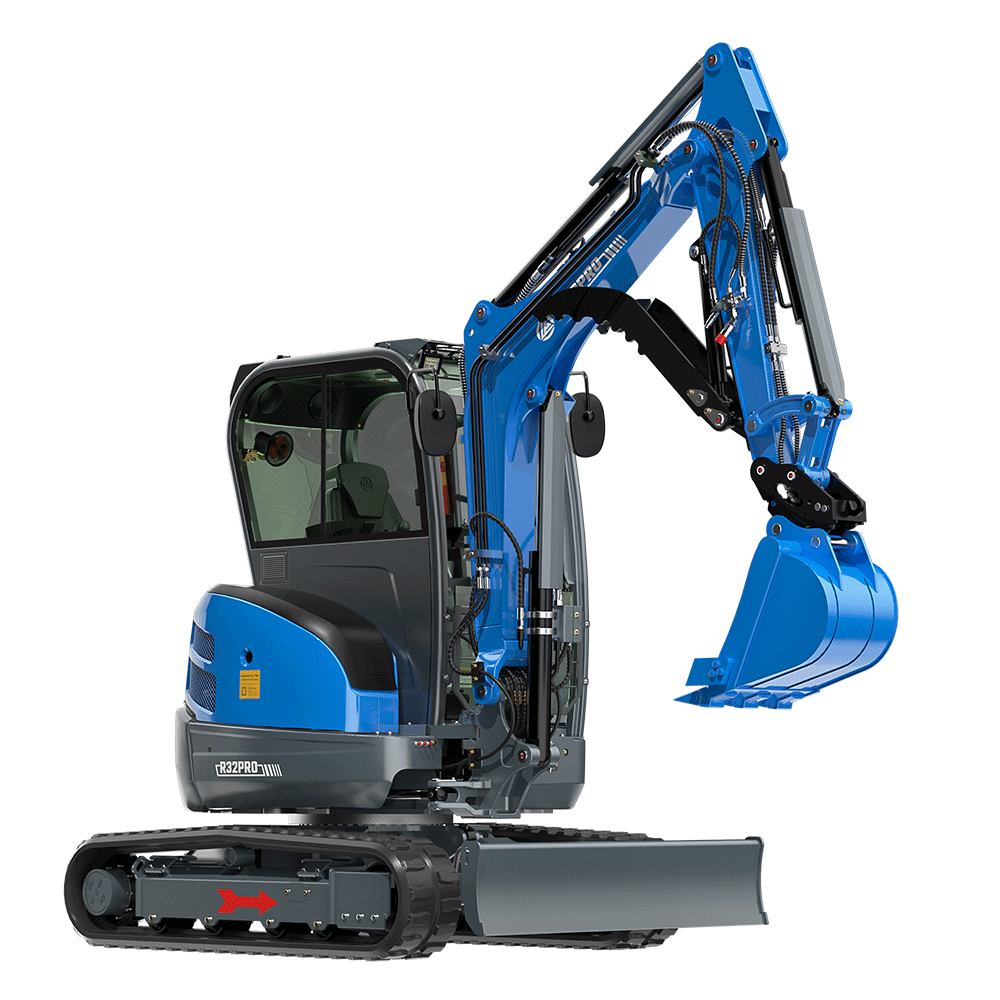

Beyond its internal power, the machine is built for structural durability and operational range. It boasts a maximum digging force of 18.4kn (4136 lbf) and a bucket capacity of 0.054m³. The physical dimensions are optimized for transport and stability, with a transport length of 2824mm, a height of 2361mm, and a variable track width. The track extension range allows the machine to shrink to 1300mm for narrow access or expand to 1500mm for maximum stability during heavy excavation, ensuring it can perform in environments where larger machines simply cannot fit.

Dynamic Operating Range and Maneuverability

Precision in the field is defined by the R32 PRO’s extensive working envelope, which allows operators to tackle deep trenches and high loading tasks with ease. The machine offers a maximum digging depth of 2293mm (90.3 in) and a maximum digging radius of 4255mm (167.5 in). For loading and unloading, it reaches a maximum height of 3761mm (148.1 in) and an unloading height of 2496mm (98.3 in). These parameters, combined with a 125-degree maximum deflection angle, provide the flexibility needed for complex landscaping, utility work, and urban construction projects.

Maneuverability is further enhanced by the dual-speed travel system, which allows the operator to switch between a low speed of 1.5 Km/h and a high speed of 2.8 Km/h. The machine is capable of handling a 30% gradeability, allowing it to navigate uneven terrain with confidence. Ground pressure is kept to a minimal 33.4kpa (4.8 psi), protecting delicate surfaces while maintaining the traction provided by its engineering rubber tracks. The inclusion of a straight running circuit ensures that the excavator maintains a stable path even when the front equipment is being operated while driving, preventing meandering or unexpected speed changes.

The R32 PRO also features specialized design elements that cater to professional versatility. It is equipped with an explosion-proof valve to maintain safety if a hydraulic pipeline is compromised, and a dedicated service port with ample oil flow for attachments such as breakers. For those in the vegetation management sector, the machine includes a lawn mower return line reservation, simplifying the future installation of auxiliary equipment. These design choices ensure that the R32 PRO is not just an excavator, but a multi-functional tool carrier suited for diverse job site requirements.

Operator Comfort and Maintenance Efficiency

The R32 PRO is designed with a "driver-centered" philosophy, ensuring that safety and comfort are never secondary to performance. The cab is available in ROPS (Roll Over Protective Structure) and TOPS (Tip-Over Protective Structure) specifications, featuring a safety structure designed to protect the operator in the event of an overturn or from falling objects. Inside, the cabin is remarkably spacious, offering generous foot space and an adjustable shock-absorbing seat with customizable height, backrest angle, and armrests. Standard equipment includes a heater, ashtray, and a front window that can be opened to enhance air circulation in high-temperature environments.

Technology plays a vital role in the operator's experience through an intelligent large-screen display. This smart monitor provides real-time data on machine parameters and uses warning lights and error codes to notify the driver of any abnormalities, such as overheating or charging system issues. This simple, easy-to-read interface allows for "one-touch" operation and ensures the driver always has full situational awareness of the machine's health. For extreme climates, the cab is equipped with an air conditioner as standard, providing a comfortable climate whether working in the mid-summer heat or extreme winter cold.

Maintenance is streamlined through a "smart maintenance" design featuring a double-opening engine hood. Both the rear and right-side bonnets can be opened wide without the need for tools, allowing for rapid daily inspections of the engine, fuel system, and filters. Internal components such as the diesel filter, air filter, and water tank are all positioned for easy access. Additionally, the hydraulic system's inspection points are centrally located on the right side of the machine, dramatically improving service efficiency and reducing downtime for the owner.