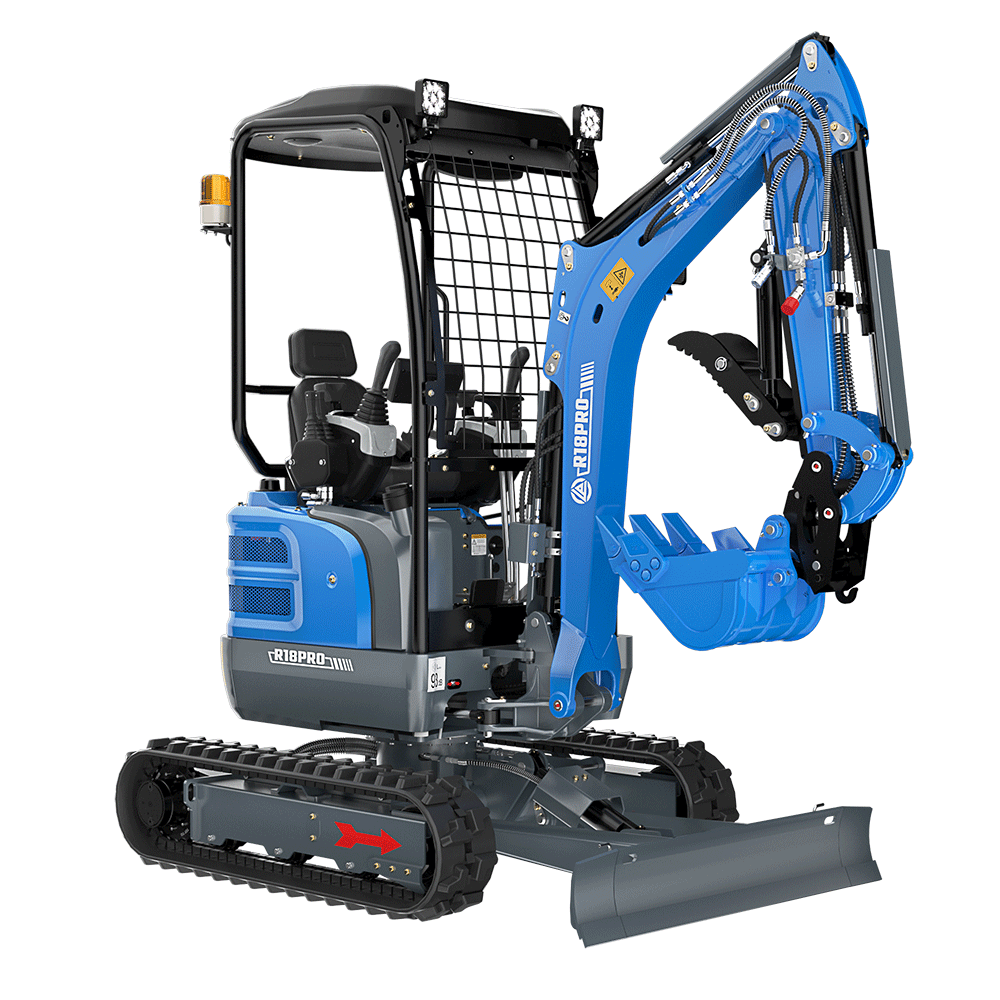

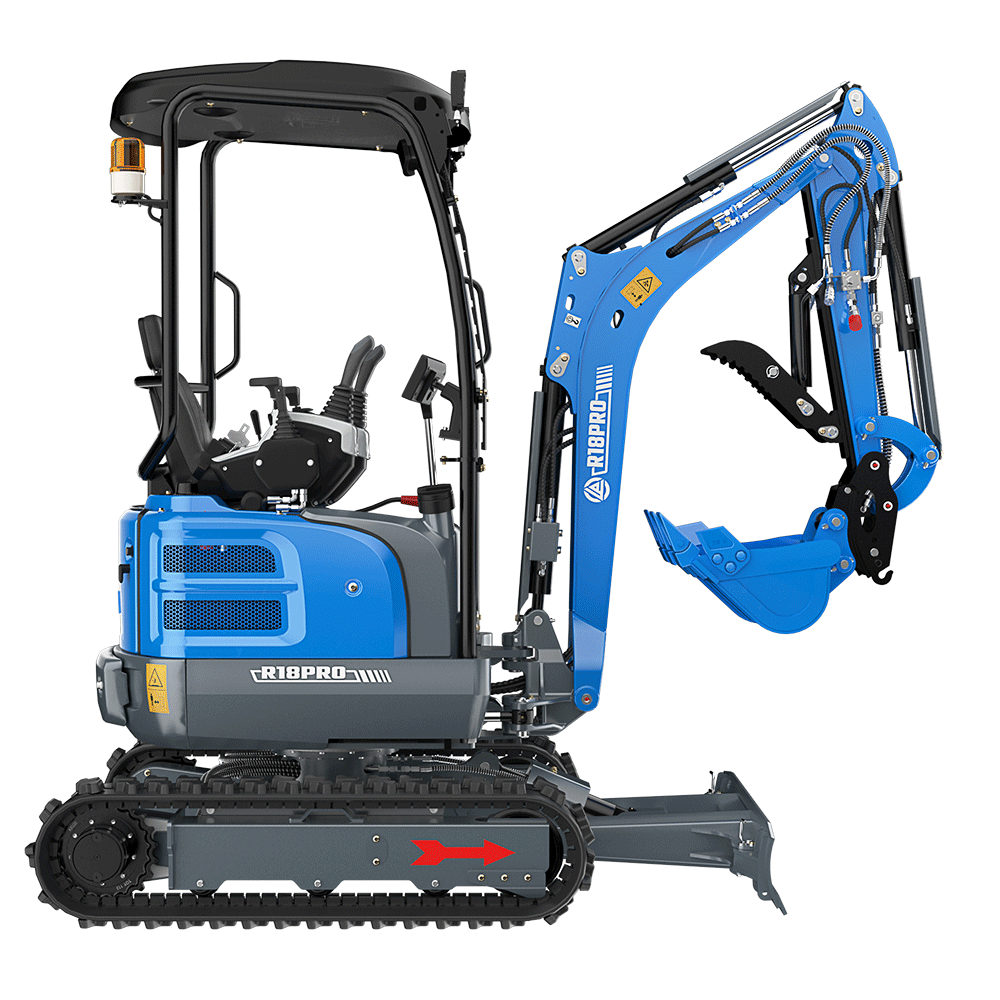

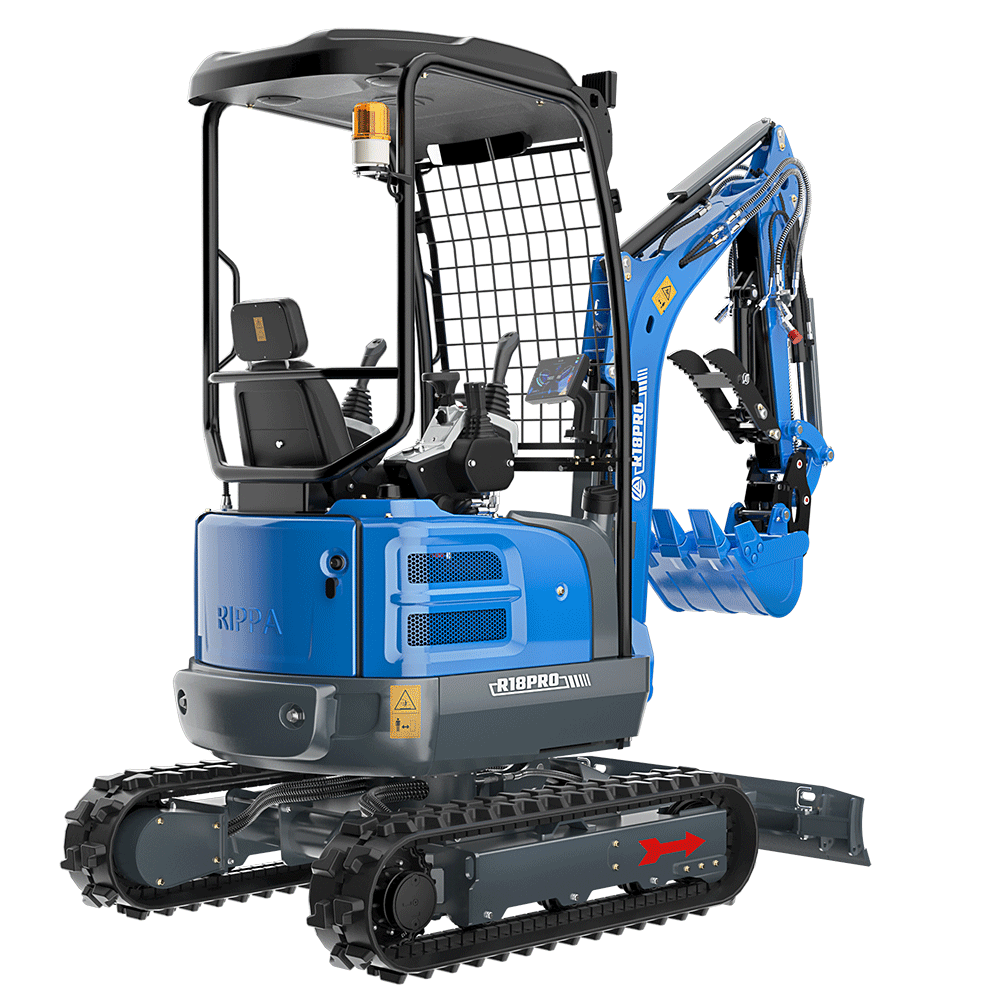

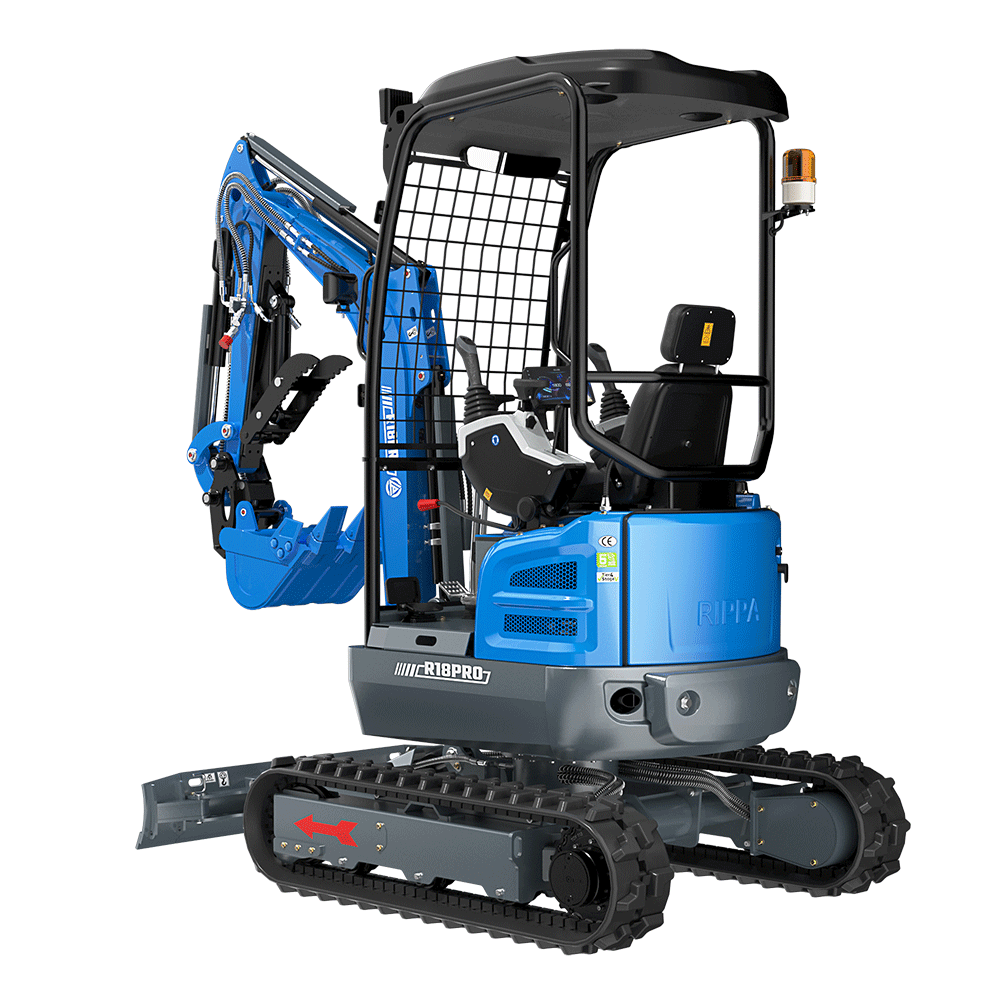

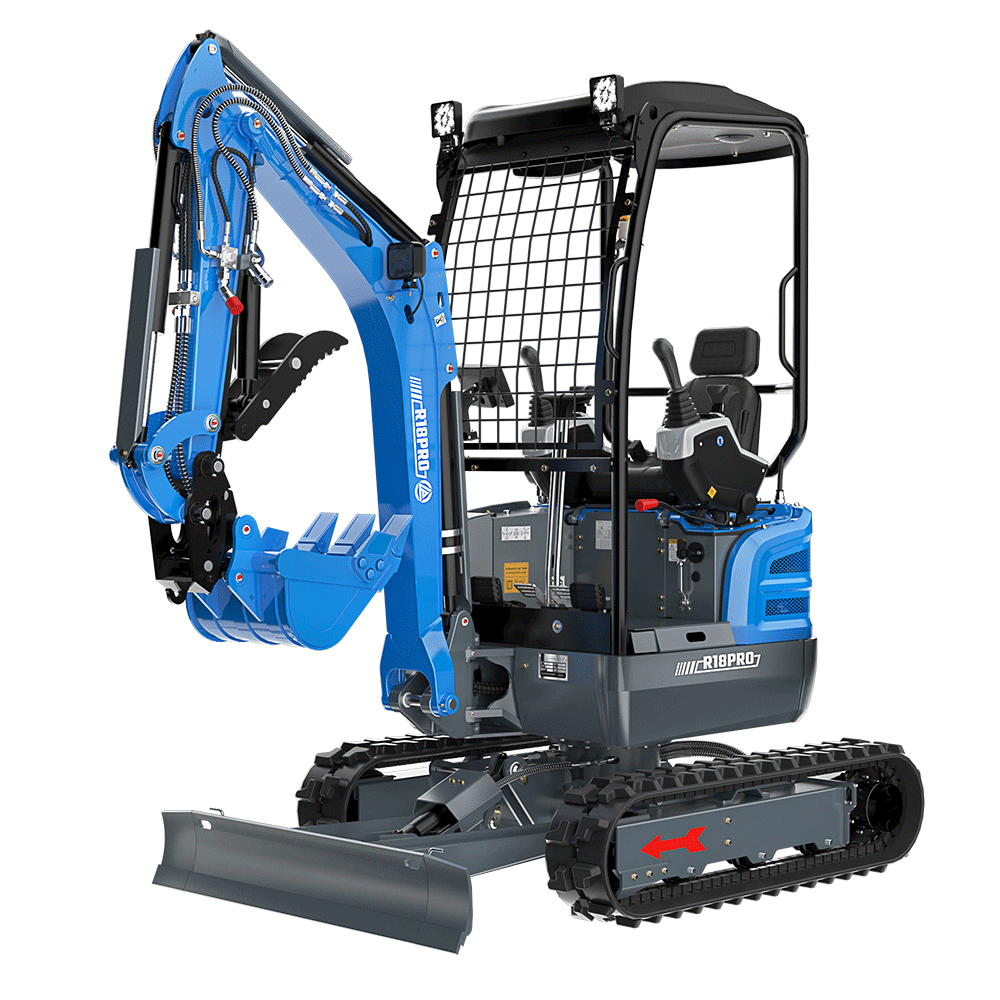

new rippa excavator for sale

Global Agent Recruitment

We are now recruiting agents worldwide!

Ideal for businesses and dealers – Start with just one unit for your overseas warehouse.

Tailored for construction projects – Wholesale only, not for retail.

Local inventory advantage – Warehouses near you ensure fast delivery and a full range of accessories.

24/7 customer support – Always here to assist you.

👉 Fill in your details, get a quick quote, and join us as our valued agent today!

Applications of Mini Excavators That Improve Work Efficiency

Mini excavators are compact yet powerful construction machines designed to deliver outstanding productivity in narrow spaces and complex working environments. They play a vital role in urban construction, road maintenance, landscaping, agriculture, utility engineering, and indoor demolition projects. Their small size allows them to enter spaces that large excavators cannot reach, significantly improving work efficiency and reducing labor costs.

One of the major uses of mini excavators is trenching for water lines, electrical cables, and drainage systems. Compared to manual digging, a mini excavator completes trench construction quickly and consistently, while maintaining precise depth control. Their advanced hydraulic control system offers smooth operation and stable digging performance, making them ideal for precision engineering.

Mini excavators are also widely used in landscaping and agricultural applications. With attachments such as augers, rakes, and buckets, they can be used for tree planting, land leveling, ditch excavation, and material loading. The rubber tracks minimize ground damage, making them suitable for working on lawns, farms, and paved surfaces. Due to their compact structure and low fuel consumption, mini excavators provide economical operation while delivering excellent productivity.

How to Select a High-Quality Mini Excavator

Choosing a reliable mini excavator requires evaluating job requirements, working conditions, and machine performance. One important factor is digging depth and operating weight. If the job requires deep trenching or lifting heavy materials, a model between 2 to 3.5 tons may be suitable. For small-scale household construction or landscape work, a 0.8 to 1.2 ton model offers convenient operation and easier transportation.

Engine performance and hydraulic system capability are also key considerations. A high-quality engine ensures adequate power output and fuel efficiency. Meanwhile, the hydraulic system determines how smoothly the mini excavator operates. Models equipped with advanced hydraulic systems provide precise control, faster movement, and high work efficiency. Load-sensing hydraulic systems are preferred because they adjust oil flow automatically, reducing energy loss and extending component lifespan.

Durability and machine structure are also essential. Look for reinforced booms, strong chassis design, and high-quality track materials. Safety and comfort features should not be overlooked—ergonomic joysticks, safety frames, protective guards, and wide operator vision enhance both safety and productivity. Finally, maintainability is an important factor. Machines with easily accessible maintenance points, protected hydraulic lines, and durable components reduce long-term repair costs.

Advantages of Rippa Mini Excavators

Rippa mini excavators are engineered with advanced hydraulic control, enhanced safety protection, and robust design to meet global customer demands. They are designed for heavy-duty construction while ensuring operator comfort and easy operation. The machine adopts hydraulic quick-change control with a tilt switch and dual mechanical safety lock, ensuring secure and fast attachment replacement during work.

The hydraulic quick coupler pipeline layout is optimized for better durability and easier maintenance. Rippa mini excavators now feature four-way high-pressure breaker pipelines with reserved return oil lines for grass cutters, allowing multiple hydraulic attachments to work efficiently. The dual-button joystick design allows operators to easily switch boom swing and rotation functions using the left joystick, greatly improving working flexibility. To adapt to international user habits, Rippa adds a control pattern switch (ISO/SAE), allowing operators to select forward or reverse hand control.

Safety has been significantly upgraded. The warning light is now bolt-mounted instead of magnetic, preventing it from falling off during rugged operations. A new explosion-proof valve prevents the boom from dropping suddenly in case of hydraulic failure. The overall hydraulic hose layout has been optimized to prevent friction damage and extend service life. Cylinder grease nipple protection covers and pointed grease nipples are added to improve lubrication and protect critical components.

Rippa mini excavators are also equipped with engine compartment heat insulation pads to reduce high temperature damage and maintain consistent engine performance. The ignition switch now features a rubber protective cover to prevent dust and water entry. For better operator comfort and safety, the machine uses rubber anti-slip floor mats, providing a stable operating platform and reducing fatigue during long working hours.

These combined innovations make Rippa mini excavators durable, efficient, and easy to operate, offering excellent performance across a wide range of working applications such as construction, agriculture, municipal maintenance, and landscaping.

Submitted successfully

We will contact you as soon as possible