small skid steers for sale

🌍 Global Distributor Recruitment

RIPPA Machinery Group is now expanding worldwide and looking for reliable distributors to join our global network!

Our machines are fully certified with CE, EPA, Euro 5, and TUV, delivering the quality and performance trusted by customers around the world.

Why Partner With RIPPA?

🚚 Local Stock Advantage – Nearby warehouses for fast delivery and complete spare parts support.

🧰 Global After-Sales Service – Multiple international service centers offering professional technical support.

💪 Wide Product Range – Excavators, loaders, skid steers, forklifts, and more.

👉 Join Us Today!

Submit your details to receive a quick quote and become an official RIPPA distributor!

Maximizing Performance with Specialized Attachments

The true power of a compact mini skid steer loader lies in its ability to transform into a completely different machine in minutes through a simple change of attachments. This core feature transforms what might seem like a simple machine into a versatile powerhouse capable of tackling a vast array of tasks. For businesses and contractors looking to optimize their equipment investment, understanding the attachment ecosystem is crucial. The right implement can turn your loader into a dedicated trencher, a powerful breaker, or a precise landscaping tool, effectively replacing multiple single-purpose machines.

Beyond the basic bucket, the market offers dozens of specialized attachments designed to handle specific materials and jobs with greater efficiency. This system is driven by the machine's auxiliary hydraulics, providing the necessary power to operate everything from augers to brush cutters. The key to maximizing your mini skid steer loader's return on investment is selecting a core set of attachments that align with your most frequent applications, ensuring the machine remains productive and valuable across different projects and seasons.

Core Attachments for Earthmoving and Material Handling

The foundation of any mini skid steer loader setup begins with attachments for moving and shaping earth. The standard general-purpose bucket is the most common starting point, ideal for loading loose materials like soil, gravel, and mulch, as well as light digging and backfilling. For more specialized earthwork, a trencher attachment allows for the quick and precise digging of narrow ditches for utilities, irrigation, or drainage lines, significantly outperforming a bucket in speed and accuracy.

For grading and finishing work, a land plane grader or a landscape rake is indispensable. These attachments are perfect for creating a smooth, level surface on driveways, building pads, or landscape beds. When dealing with heavy, compacted materials like clay or frost, a soil conditioner or a tiller attachment can break up and aerate the ground, preparing it for planting or construction. For lifting and transporting palletized goods, forklift attachments provide the lifting capacity and stability needed to move materials around a job site or warehouse safely and efficiently.

Attachments for Demolition, Landscaping, and Specialized Tasks

Expanding into more demanding applications, hydraulic breakers are essential attachments for any mini skid steer loader involved in demolition or construction. These powerful tools efficiently break up concrete, asphalt, and rock, making them perfect for patio removal, foundation work, or trenching through hard surfaces. Their power, combined with the machine's mobility, makes them a formidable alternative to larger, less maneuverable equipment.

In the realm of landscaping and property maintenance, the attachment options are vast. A rotary broom or sweeper cleans up debris, gravel, and light snow from paved surfaces. For vegetative management, a brush cutter attachment can clear heavy brush, small trees, and overgrowth, while a stump grinder can remove unsightly tree remnants. In winter, a snow blower or a plow attachment transforms the loader into a highly effective snow-clearing machine. For agricultural or large property use, a bale spear simplifies handling hay bales, and a grapple bucket is perfect for moving irregularly shaped loads like rocks, logs, or demolition debris.

The Engine Powering Performance: Kubota V1505 and Euro 5 Compliance

At the heart of reliable performance for machines like the R32 compact excavator is the Kubota V1505 engine, renowned for its durability and efficiency. This engine is engineered to meet the stringent Euro 5 compliance standards, representing a significant step forward in reducing environmental impact without sacrificing power. The advanced emission control technology ensures lower levels of nitrogen oxides and particulate matter, making it a responsible choice for urban job sites and environmentally sensitive areas.

The Kubota V1505 engine delivers the robust torque and consistent power output necessary for demanding tasks such as digging foundations, trenching for utilities, or operating high-flow hydraulic attachments. Its design prioritizes fuel efficiency, translating to lower operating costs and extended work periods between refueling. This combination of Euro 5 compliance and proven Kubota engineering means operators benefit from a machine that is both powerful and clean-running, ensuring it meets current regulations and remains a viable asset for years to come.

Advanced Hydraulic and Safety Systems for Enhanced Operation

Modern compact equipment integrates sophisticated hydraulic and safety features to protect both the machine and the operator. A critical safety component is the inclusion of an Anti-Cavitation Valve. This system is designed to react within an impressive 50 milliseconds, instantly preventing the boom from free-falling in the event of a hydraulic hose failure. This rapid response dramatically reduces the risk of equipment damage and enhances on-site safety during lifting or precision digging operations.

Further improving durability and uptime is the integration of features like a grease nipple protection block. This simple yet effective design shields crucial lubrication points from damage caused by debris and impacts during operation. By extending the life of these components, it reduces maintenance frequency and helps keep the machine in optimal working condition. Additionally, the inclusion of a Four-Way Hydraulic Hammer Hose Circuit provides remarkable flexibility, allowing the operator to quickly switch between multiple auxiliary tools—such as a breaker, auger, or grapple—without complex re-plumbing, boosting job site efficiency.

Operator-Centric Design for Productivity and Comfort

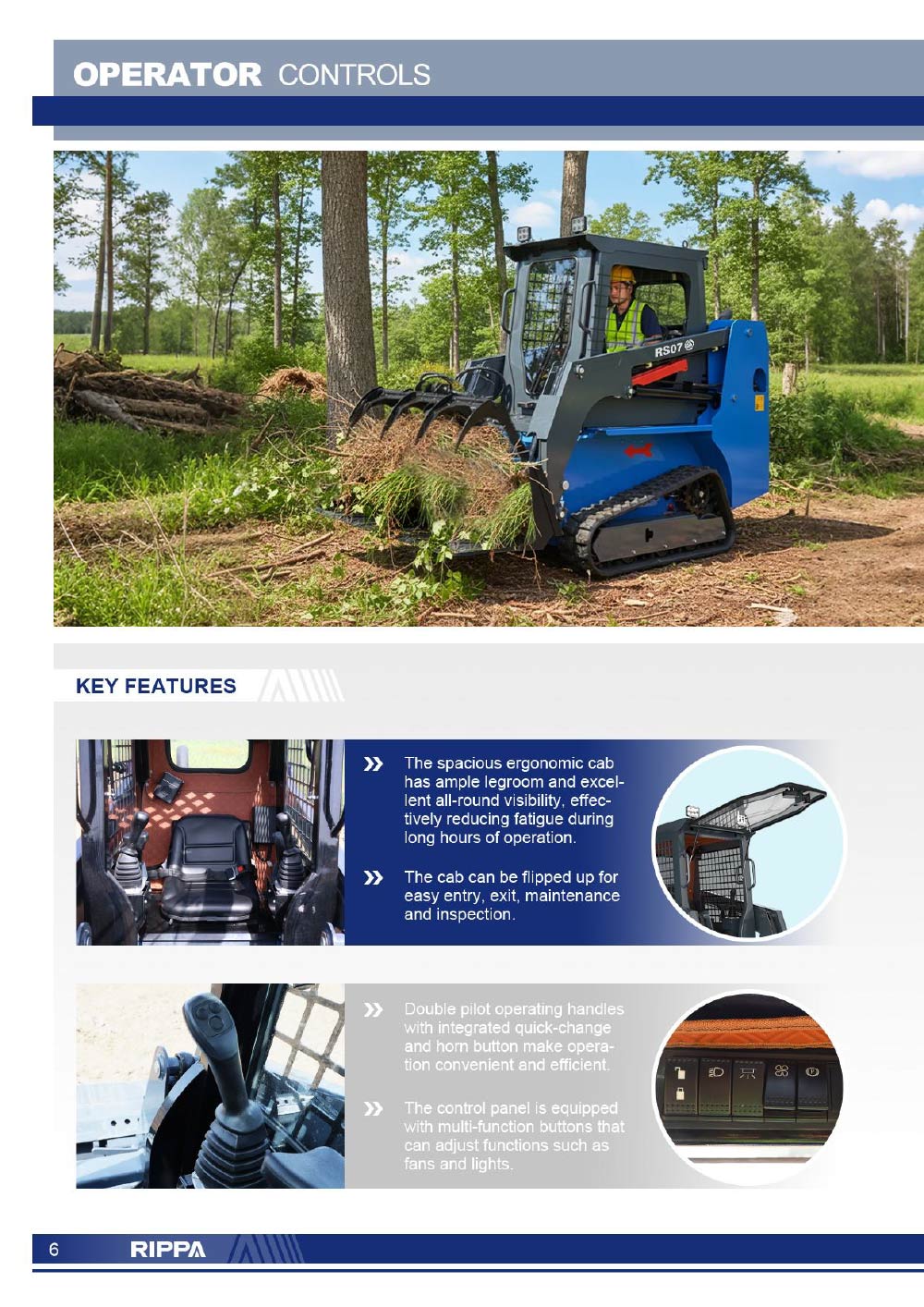

Recognizing that operator comfort directly impacts productivity, modern machines are designed with the user in mind. Ergonomic controls, such as joysticks with integrated multi-function buttons, allow for intuitive operation of the machine and its attachments. This design reduces the learning curve for new operators and minimizes hand movement, decreasing fatigue over long working days. The cab environment is also a focus, with easy-to-read displays and logically placed controls.

To further combat operator fatigue, features like a multi-adjustable air-ride suspension seat are paramount. These seats significantly dampen machine vibration and provide crucial lumbar support, allowing operators to work more comfortably for extended periods. When combined with easy attachment changeover systems—like hydraulic quick couplers with safety locks—the machine becomes not only more comfortable to operate but also quicker and safer to reconfigure for different tasks. This holistic approach to the operator's experience ensures that the machine's full potential can be realized efficiently and sustainably.

Related News

Submitted successfully

We will contact you as soon as possible