mini skid steer trencher

Global Agent Recruitment

CE, EPA, Euro5, and TUV certified.

We are now recruiting agents worldwide!

Ideal for businesses and dealers – Start with just one unit for your overseas warehouse.

Tailored for construction projects – Wholesale only, not for retail.

Local inventory advantage – Warehouses near you ensure fast delivery and a full range of accessories.

24/7 customer support – Always here to assist you.

👉 Fill in your details, get a quick quote, and join us as our valued agent today!

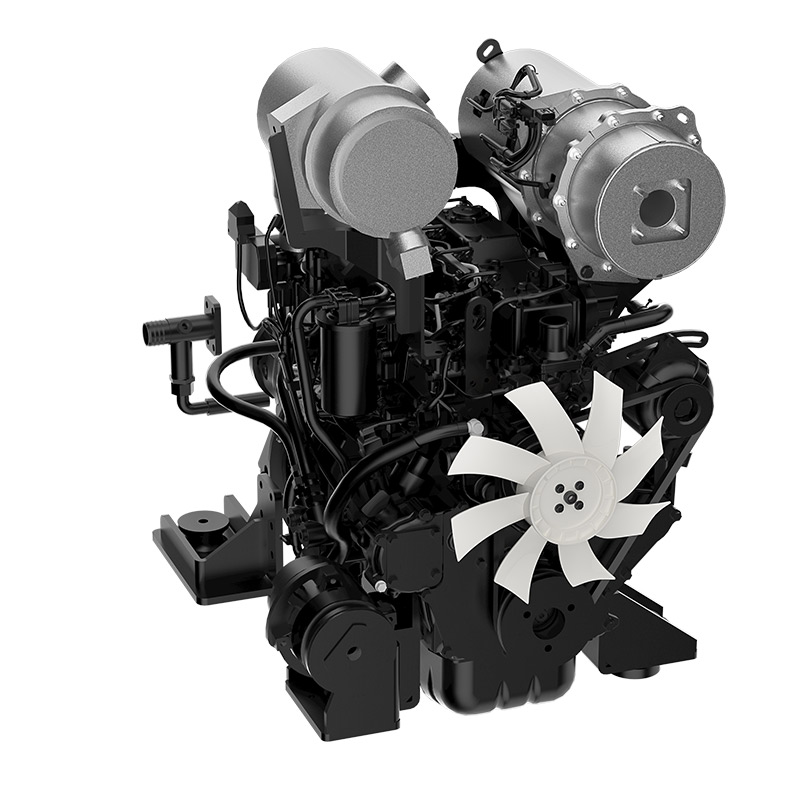

Powerful Yanmar Engine and High-Efficiency Performance

The RIPPA RS20 skid steer loader is engineered to tackle high-intensity and high-load working environments with ease, making it an ideal choice for large-scale construction sites, mining operations, and heavy equipment handling

Beyond raw power, the RS20 is built for operational efficiency and sustainability. The engine design focuses on lower fuel consumption and reduced vibration without compromising on torque, which significantly improves overall processing performance

To maximize productivity, the RS20 features a double-speed motor capable of reaching travel speeds of up to 10 km/h (6.2 mph)

Advanced Hydraulic System and Versatile Attachments

The RS20 is equipped with a sophisticated four-pump hydraulic system that ensures smooth, stable, and highly responsive operation

Versatility is a hallmark of the RS20, thanks to its industry-standard quick coupler that is compatible with dozens of mainstream attachments

Durability is built into every hydraulic component. The hydraulic oil cylinders feature a strengthened, integrated design that reduces welding seams, preventing the breakage that often occurs in high-stress applications

Ergonomic Design and Maintenance Convenience

Operator comfort is prioritized through an ergonomic cab design that introduces the concept of specialized "functional areas"

The control interface is designed for intuitive use, featuring ergonomically controlled electronic joysticks and a centralized switch layout

Maintenance for the RS20 is designed to be as simple and time-efficient as possible. All primary maintenance points are concentrated at the rear of the machine, and the back cover opens easily to provide one-stop access to components and pipelines without the need to lift the cab

Submitted successfully

We will contact you as soon as possible