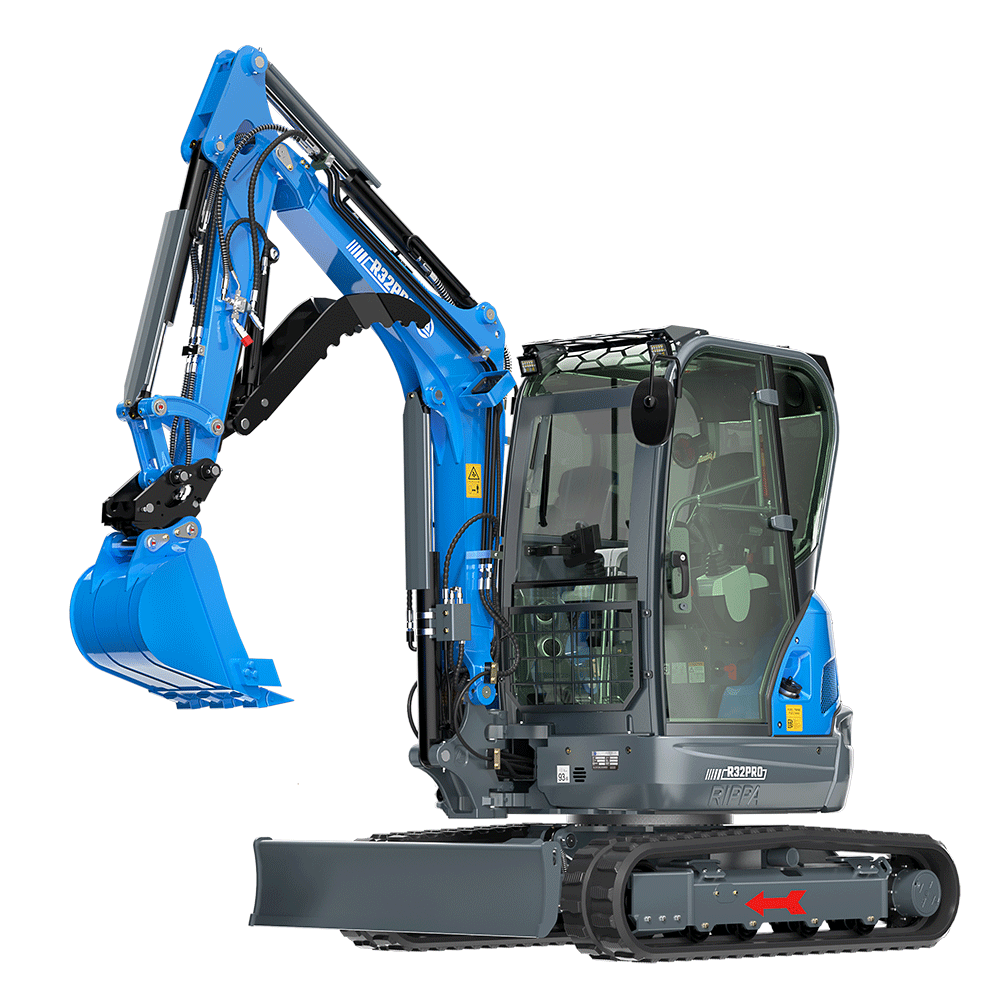

mini excavator for sale new

🌍 Global Distributor Recruitment

RIPPA Machinery Group is now expanding worldwide and looking for reliable distributors to join our global network!

Our machines are fully certified with CE, EPA, Euro 5, and TUV, delivering the quality and performance trusted by customers around the world.

Why Partner With RIPPA?

🚚 Local Stock Advantage – Nearby warehouses for fast delivery and complete spare parts support.

🧰 Global After-Sales Service – Multiple international service centers offering professional technical support.

💪 Wide Product Range – Excavators, loaders, skid steers, forklifts, and more.

👉 Join Us Today!

Submit your details to receive a quick quote and become an official RIPPA distributor!

Advantages of Choosing a Rippa Mini Excavator

When considering the purchase of a mini excavator, price is naturally a key factor, but understanding the cost-effectiveness of these machines is equally important. Rippa mini excavators leverage cutting-edge technology to significantly enhance their performance and efficiency.

Rippa is known for producing compact machines that offer excellent value for money without compromising on quality. Their mini excavators are designed for various tasks, from construction to landscaping, and are built to provide long-lasting reliability, ease of operation, and high productivity. Here are some standout features of Rippa mini excavators:

High-Resolution LCD Display

One of the standout features of Rippa mini excavators is their high-resolution LCD display. This clear, bright screen offers a user-friendly interface, making it easy for operators to monitor crucial machine parameters. The display shows real-time data on engine speed, hydraulic pressure, fuel levels, and temperature, allowing operators to stay on top of the machine’s status. This feature not only improves operational efficiency but also provides alerts before potential issues worsen, enhancing safety on the job site.

Adjustable Arm and Bucket Positioning

Rippa mini excavators are equipped with an adjustable arm, allowing for versatile operation. The positioning of the arm’s teeth can be easily adjusted in any direction based on the attachment being used. Operators can quickly switch between various attachments, such as buckets or levelers, using a handheld toggle button. This function significantly speeds up the attachment change process, making the Rippa mini excavator incredibly efficient, particularly in environments where multiple attachments are required for different tasks.

Speed Control for Enhanced Efficiency

Another important feature is the manual speed control system. Operators can select between fast or slow modes, allowing the machine to adapt to various work conditions. Whether it's precision landscaping or heavy-duty digging, adjusting the speed ensures the excavator performs at optimal efficiency. This ability to control speed means operators can tailor the machine’s performance to the specific needs of the task, whether they need more digging power or finer control for delicate work.

Dual-Safety Hydraulic Quick Coupler

Rippa mini excavators come with a dual-safety hydraulic quick coupler system. This system can only be activated by pressing a red safety button, ensuring the hydraulic quick coupler engages only when it is safe to do so. This safety mechanism prevents the accidental coupling of attachments, reducing the risk of damage to the machine and attachments. By offering this added layer of security, Rippa ensures that the mini excavator operates smoothly and reliably, minimizing the chances of unexpected issues during operation.

Applications of Mini Excavators

Mini excavators, especially those from Rippa, are extremely versatile machines that can be used in a wide variety of applications. Their compact size and powerful capabilities make them ideal for jobs that require both strength and precision. Some common applications include:

Landscaping: Rippa mini excavators are perfect for digging trenches, installing irrigation systems, or moving soil for landscaping projects. Their small size allows them to work in tight spaces, making them an excellent choice for residential and urban projects.

Construction: On construction sites, these machines are invaluable for tasks such as trenching, foundation digging, or moving small amounts of material. Their maneuverability allows them to work in confined spaces, making them an essential tool for smaller building projects.

Agriculture: Mini excavators are also used in agriculture for tasks like digging drainage channels, planting trees, and performing small-scale excavation work. Their compact size allows them to access hard-to-reach areas without damaging crops or existing structures.

Utility Work: For utility companies, mini excavators are ideal for digging small trenches for laying pipes or cables, particularly in areas with limited space or difficult terrain.

Attachments for Mini Excavators

Mini excavators are highly adaptable thanks to the variety of attachments that can be used with them. These attachments significantly expand the machine’s functionality, making it suitable for a broad range of tasks. Some common attachments for mini excavators include:

Buckets

Buckets of various sizes and shapes are the most common attachment for mini excavators. They are used for digging, scooping, and lifting materials like dirt, gravel, and debris. A mini excavator with a high-quality bucket can handle both light and heavy digging tasks efficiently.

Hydraulic Hammers

For tougher tasks, such as breaking concrete or rocks, a hydraulic hammer attachment can be used. These powerful tools allow mini excavators to perform demolition work in environments that would typically require much larger machines.

Augers

Augers are used for drilling holes, which can be particularly useful for planting trees, installing posts, or digging foundation holes. This attachment allows the mini excavator to drill deep into the ground quickly and efficiently.

Grapples

Grapple attachments are perfect for handling materials such as wood, scrap, and construction debris. They can be used to pick up and move large, heavy objects, providing additional flexibility for a mini excavator.

Rippers

For breaking through hard soil, clay, or ice, a ripper attachment can be extremely useful. The ripper can penetrate tough materials, allowing the mini excavator to perform tasks such as trenching or removing rocky soil.

Mulchers

For land clearing, mulchers can be attached to mini excavators. These attachments grind up small trees, brush, and debris, helping to clear an area quickly.

Rippa mini excavators, with their efficient attachment compatibility, are designed to handle a wide range of tasks, making them suitable for various industries and project types. Their ability to easily swap between attachments makes them a must-have for operators who require flexibility and efficiency on the job site.

Related News

Submitted successfully

We will contact you as soon as possible