mini skid loaders for sale

🌍 Global Distributor Recruitment

RIPPA Machinery Group is now expanding worldwide and looking for reliable distributors to join our global network!

Our machines are fully certified with CE, EPA, Euro 5, and TUV, delivering the quality and performance trusted by customers around the world.

Why Partner With RIPPA?

🚚 Local Stock Advantage – Nearby warehouses for fast delivery and complete spare parts support.

🧰 Global After-Sales Service – Multiple international service centers offering professional technical support.

💪 Wide Product Range – Excavators, loaders, skid steers, forklifts, and more.

👉 Join Us Today!

Submit your details to receive a quick quote and become an official RIPPA distributor!

Durable Design and Advanced Product Features of the Rippa RS10

The Rippa RS10 mini skid steer loader is engineered with a strong emphasis on durability, precision, and real-world jobsite performance. Its compact structure, combined with an optimized internal layout, allows the machine to deliver professional-grade productivity while remaining easy to transport and maneuver in confined spaces. Every core component is carefully selected to enhance efficiency, reliability, and long-term operating value, making the RS10 a practical solution for construction, landscaping, agriculture, and municipal maintenance applications.

A defining feature of the RS10 is its four-wheel-drive configuration, which provides excellent driving stability and balanced weight distribution. This layout significantly improves traction on uneven or soft ground while maintaining smooth and predictable control during turning and lifting operations. The robust chassis design ensures consistent performance across a wide range of working conditions, from paved urban environments to rugged outdoor terrain.

Thermal management is another key strength of the RS10. The machine is equipped with a large-capacity, high-efficiency radiator designed to handle continuous high-load operation and hot climate conditions. By maintaining stable operating temperatures, the cooling system protects critical components from overheating, improves overall system reliability, and extends the service life of both the engine and hydraulic components. This attention to heat dissipation reflects the RS10’s focus on long-term durability and dependable performance.

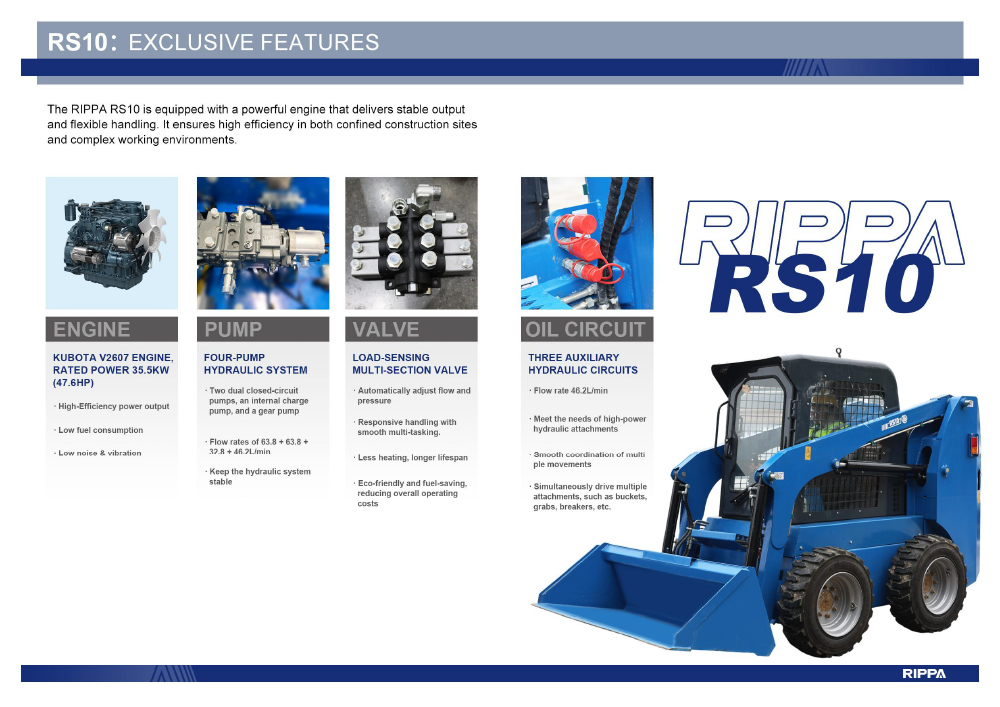

Engine Performance and Operational Efficiency

The Rippa RS10 mini skid steer loader is powered by the globally recognized Kubota V2607 diesel engine, known for its reliability, efficiency, and consistent power delivery. With a rated output of 35.5 kW (47.6 HP), the engine provides strong and stable performance that allows the RS10 to handle demanding tasks with ease. Its power characteristics are precisely matched to the hydraulic and drive systems, resulting in smooth acceleration, responsive control, and efficient operation under varying load conditions.

Fuel efficiency is a major advantage of the RS10. The Kubota V2607 engine is designed to optimize combustion efficiency, minimizing fuel waste while maintaining high productivity. This allows operators to complete heavy-duty tasks without excessive fuel consumption, helping reduce operating costs over extended working cycles. For contractors and fleet operators seeking a balance between performance and cost control, the RS10 represents a highly economical choice.

Operator comfort and environmental suitability are further enhanced by the engine’s low noise and low vibration characteristics. Reduced vibration levels help minimize operator fatigue during long working hours, while low noise output makes the RS10 suitable for use in residential areas or noise-sensitive environments. These qualities not only improve working conditions but also highlight the machine’s refined mechanical design and commitment to environmentally responsible operation.

Hydraulic System, Attachments, and Jobsite Versatility

The Rippa RS10 features an advanced four-pump hydraulic system that ensures consistent, high-efficiency power delivery across all operating functions. This system consists of two dual-circuit closed-loop pumps, an internal charge pump, and a dedicated gear pump, with flow rates of 63.8 + 63.8 + 32.8 + 46.2 L/min. This configuration maintains stable pressure and smooth response even during complex, multi-function operations, allowing operators to work more efficiently without power interruptions.

Integrated into the hydraulic architecture is a load-sensing, multi-section valve that automatically adjusts flow and pressure based on real-time working demands. This intelligent control system delivers fast response, smooth multitasking capability, and reduced energy loss. Lower heat generation contributes to longer component life, while the overall energy-efficient design helps reduce fuel consumption and operating costs, supporting more sustainable and cost-effective jobsite operations.

Versatility is further expanded through the RS10’s three auxiliary hydraulic circuits, each delivering a flow of 46.2 L/min. This setup supports high-power hydraulic attachments and enables coordinated multi-action operation. The RS10 can simultaneously operate buckets, grapples, hydraulic breakers, and other attachments, significantly broadening its application range and increasing jobsite flexibility.

To enhance mobility and terrain adaptability, the RS10 travel system utilizes high-torque OMCR3 series piston motors. These motors provide strong driving force and reliable traction, ensuring stable movement on slopes, uneven ground, or soft surfaces. The floating bucket function automatically adjusts the bucket angle to match ground contours, keeping it close to the surface during operation. This feature greatly improves performance in cleaning, leveling, and surface finishing tasks, allowing the RS10 to handle uneven terrain with ease while maximizing overall working efficiency.

Submitted successfully

We will contact you as soon as possible