Power in the Bucket: Exploring the Anatomy of Excavators

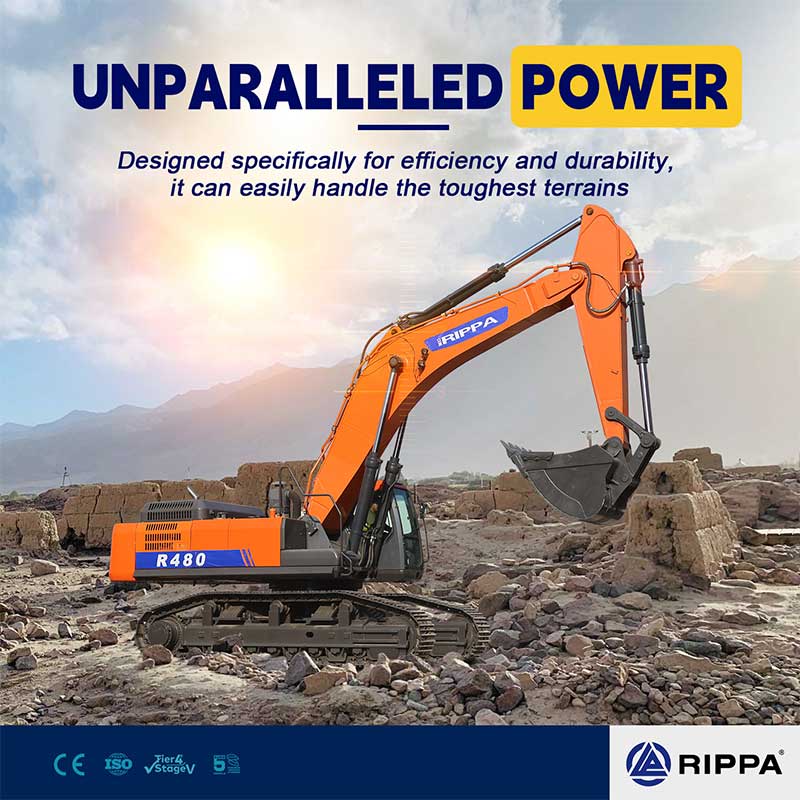

Excavators are among the most important pieces of construction machinery, essential for building, landscaping, and infrastructure development. These powerful machines can dig, lift, and transport materials with unmatched efficiency. From mini excavators suited for tight spaces to large heavy-duty models for demanding projects, there is a wide range of options to meet different requirements. Contractors across the globe rely on trusted brands like RIPPA excavators to deliver strength, durability, and versatility.

The Core Design of Excavators

At the heart of every excavator is its engine, which provides the power needed for all hydraulic and mechanical operations. Modern engines are built to be fuel-efficient and environmentally friendly, helping to reduce emissions while delivering consistent performance. This ensures that excavators remain reliable and sustainable even on long projects.

The hydraulic system is the lifeline of an excavator. It includes pumps, cylinders, and hoses that allow smooth and precise control of the boom, arm, and bucket. With this system, operators can perform delicate tasks like trenching and grading, as well as heavy digging and lifting, with accuracy and efficiency.

Equally important is the boom and arm assembly. The boom extends from the machine body, providing reach and strength, while the arm controls digging depth and flexibility. At the end of the arm, the bucket serves as the primary working tool, designed in various shapes and sizes to handle soil, rocks, or other materials. Supporting these functions are the cab for operator comfort, tracks for mobility across rough terrain, and counterweights to maintain stability during lifting tasks.

The Role of the Excavator Bucket

The bucket is the most recognizable part of an excavator and a critical factor in its performance. Its primary role is digging and excavation, allowing the machine to remove soil, rock, and debris efficiently. The shape, teeth, and capacity of the bucket determine how much material can be moved in one pass, directly influencing productivity.

Beyond digging, buckets are essential for material handling. General-purpose buckets are suitable for soil, while reinforced rock buckets are designed for more demanding conditions. Specialized buckets, such as trenching or grading buckets, increase versatility by adapting the excavator to specific jobs. Operators can switch between bucket types quickly, making the machine multifunctional and cost-effective.

Durability is another key aspect. Excavator buckets are built with heavy-duty materials to withstand wear and tear in harsh environments. High-quality buckets reduce material spillage, improve safety, and ensure smoother job site operations. With proper design and maintenance, the bucket significantly enhances the overall efficiency of the excavator.

The Importance of Hydraulic Systems

The hydraulic system is what gives the excavator its strength and precision. By transmitting pressurized fluid through pumps and cylinders, the system powers the boom, arm, and bucket. This allows for powerful yet controlled movements, which are essential for construction, trenching, and foundation work.

Hydraulic systems also make excavators versatile. Operators can easily change attachments—such as buckets, breakers, or grapples—using hydraulic quick couplers, allowing one machine to perform multiple tasks on the same site. Adjustable flow and pressure provide variable speed and force, helping operators adapt to different job demands while maximizing efficiency.

Safety features built into hydraulic systems, such as overload protection, prevent machine stress and ensure operator security. By reducing the need for mechanical linkages, the hydraulic design also simplifies maintenance and increases long-term durability. Ultimately, the hydraulic system is what transforms an excavator from a simple digging machine into a powerful, multifunctional tool trusted by contractors worldwide.