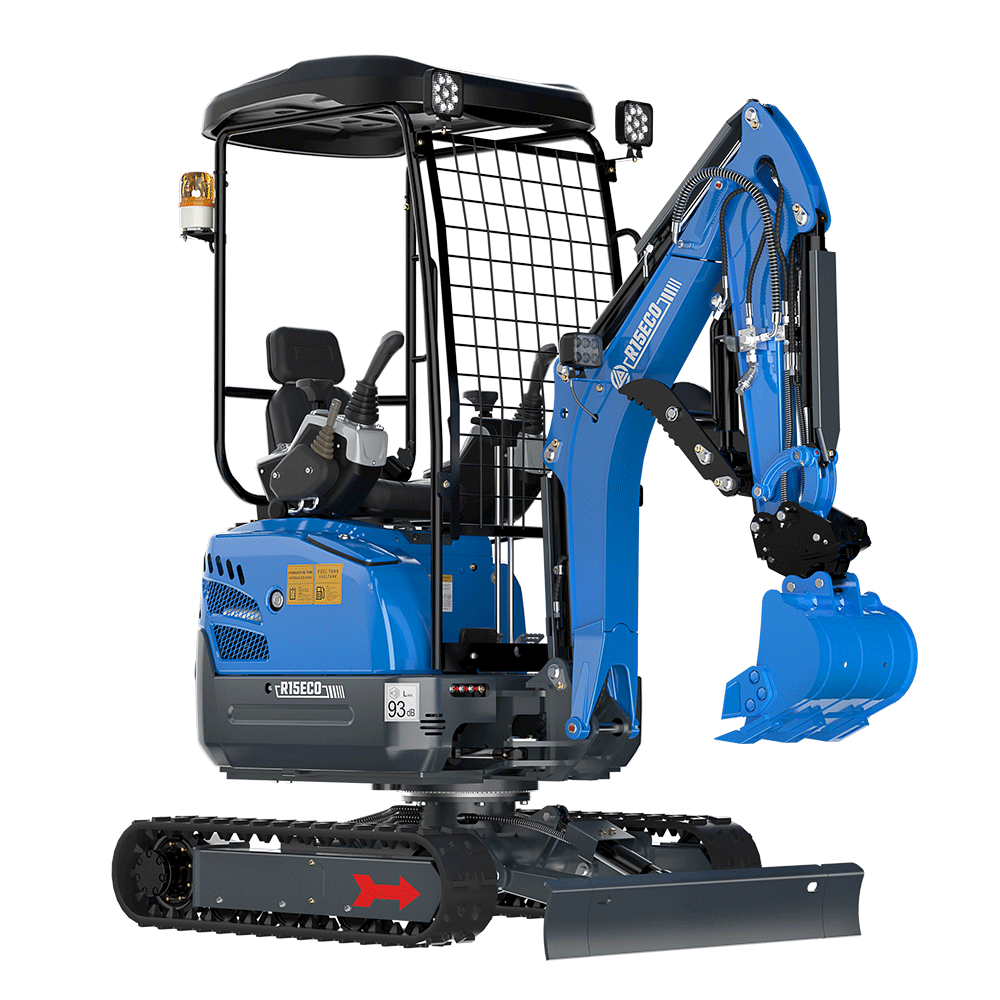

R15 excavator upgrades are coming, winning market opportunities with innovative technology

The R15 excavator has undergone a comprehensive upgrade, significantly improving its maneuverability, stability, and durability, further satisfying customer demands for efficient, safe, and comfortable construction. This upgrade primarily encompasses the hydraulic, control, and lighting systems, as well as optimization of detailed components, fully demonstrating the R15's product competitiveness.

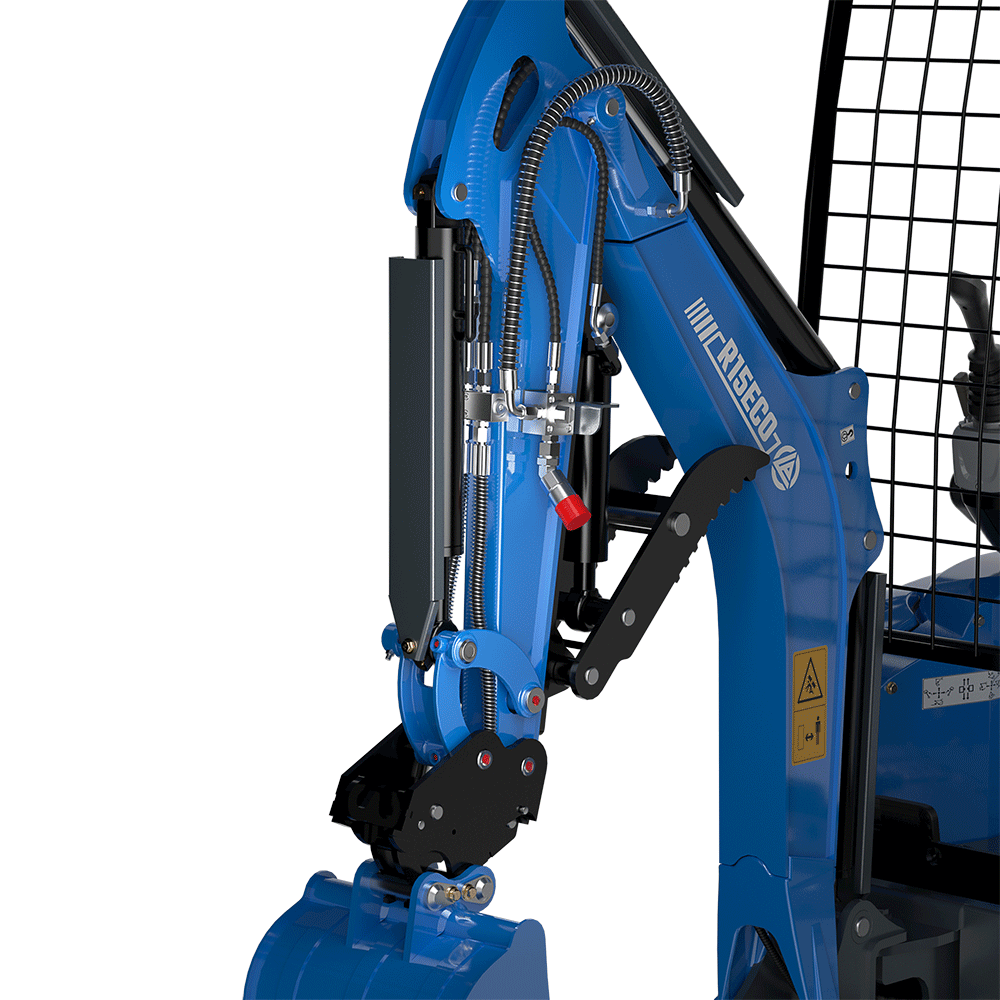

1. Hydraulic System Optimization: More Efficient Quick-Change and More Accessories

Upgraded Hydraulic Quick-Change Piping: A quick-change switching valve block is installed in the middle of the arm. This not only fixes the oil pipe routing but also connects the quick-change valve block to the hydraulic quick-change oil pipes. If a rupture occurs in the bucket end quick-change oil pipe, the user can simply replace it, making maintenance more convenient.

Optimized Hydraulic Quick-Change Switch: A new red safety switch is linked to the rocker switch, ensuring that the rocker can only be moved when the red safety is pressed, effectively preventing accidental operation and ensuring safe operation.

New Four-Channel Breaker Piping: This allows for simultaneous use of more auxiliary tools to meet diverse operating needs under different working conditions.

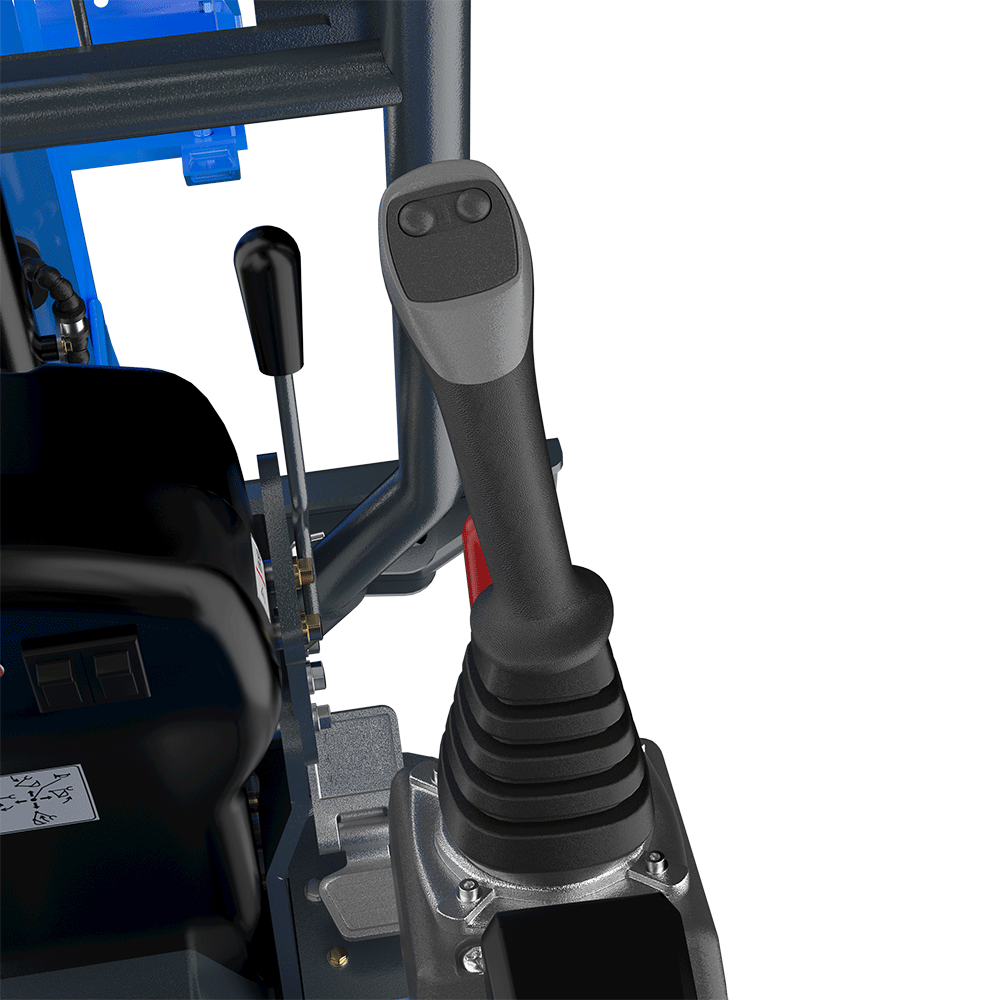

2. Control Performance Upgrade: Multi-Function Handle and Forehand/Backhand Switching

Dual-Button Handle: Both left and right handles feature dual buttons. The right hand controls the speaker, while the left hand switches between rotation and yaw. Four expansion buttons are also reserved for future functionality.

Forehand/Backhand Switching Valve: Upgraded from an optional feature to a standard feature, this manual switching valve offers more stable performance and a longer lifespan, meeting the diverse needs of both forehand and backhand control.

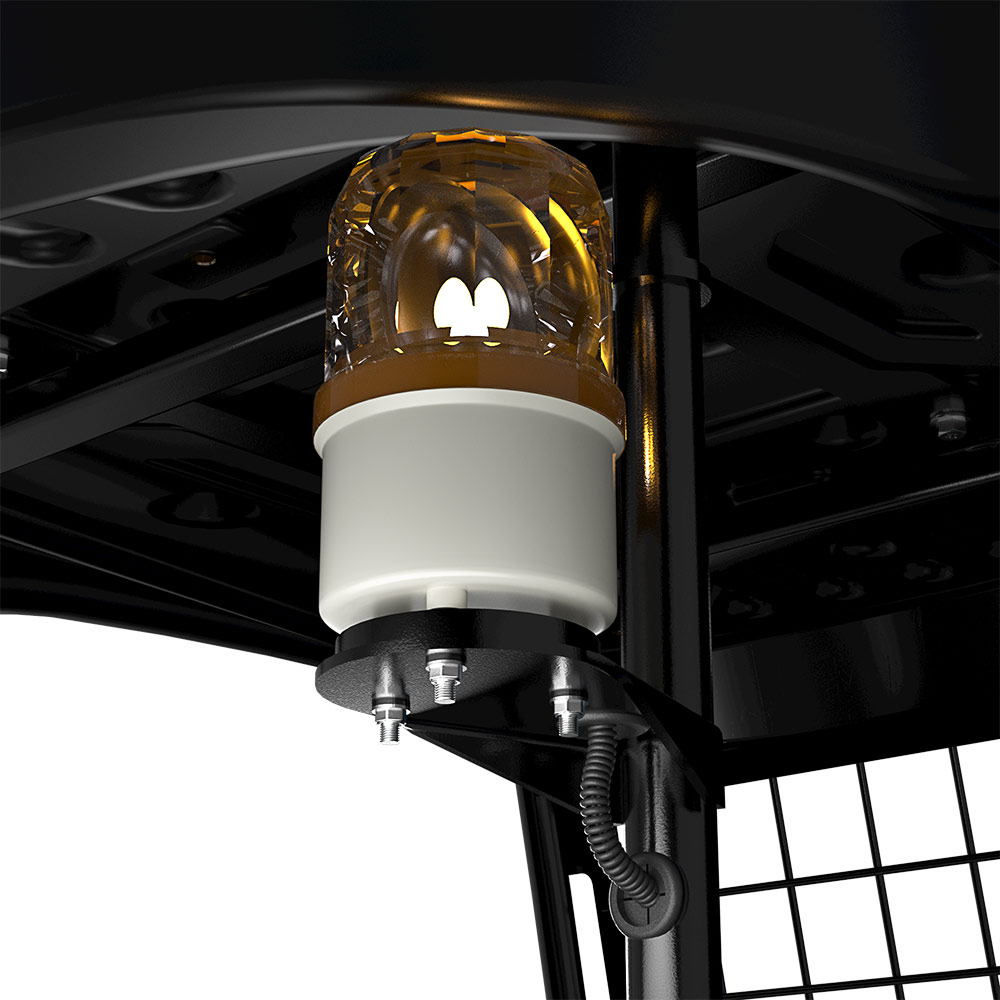

3. Enhanced Safety and Stability: Detailed upgrades for greater reliability

Improved magnetic warning light: Bolt-on mounting replaces the original magnetic method, preventing it from falling due to vibration and improving safety and reliability during construction.

Fully piloted control system: Equipped with dual and single foot valves, it provides a smoother and more stable operating experience. Optimized oil pipe routing reduces wear and extends pipe life.

4.Lighting System Upgrade: Safer Nighttime Construction.

New nine-beam high-beam headlights have been added to the ceiling. Controlled by a two-position switch, the first position provides working lights, while the second position provides a combination of working lights and high beams. This significantly enhances visibility during nighttime construction, reduces safety risks, and improves operational efficiency.

5.Improved Durability: Details Determine Quality

Nickel-Plated Tip Grease Fitting: Effectively resists corrosion from water, mud, acids, and alkalis, enhancing surface hardness and preventing deformation under high pressure.

Precise Docking: The tip design ensures more precise docking of the grease gun, minimizing slippage and oil leaks.

Welded Stop Protection: Effectively prevents damage to the grease fitting during operation.

Enhanced Maintenance: Clean the fitting before greasing, and use a high-pressure grease gun with a pressure of 3000 psi or higher to ensure adequate lubrication.